24V 48V Robot Joint Module:Choose the Write Voltage for Robots and Automation

When selecting a robot joint module, voltage matching is a key factor that directly affects the performance, safety, compatibility, and operational stability of the equipment. Electrical components such as robots, servo motors, and controllers are designed to operate within a specific voltage range. In sufficient voltage can lead to insufficient power, slow response, or even failure to start; excessive voltage may burn out the circuit or shorten its life. HONPINE's standard joint modules include two voltages: 24V and 48V. They each play a unique role to ensure the efficient operation of robots and automation equipment.

24V Joint Module: Safety-Precision Synergy

The 24V voltage is widely used in robot joint modules. Its main advantage is that it is safer. Even if the operator accidentally touches it, the risk of electric shock is reduced within the safe voltage range that the human body can bear. It is suitable for scenarios with high safety requirements.

At the same time, the 24V power supply system is relatively simple in design and has good electromagnetic compatibility. It can effectively reduce interference and ensure the stable operation of precision components such as sensors and encoders in the joint module. In some light-load robots, such as service robots, the 24V voltage is sufficient to meet their power requirements and achieve precise motion control.

48V Joint Module: Heavy-Duty Performance

The 48V voltage performs well in power transmission. Compared with 24V, at the same power, 48V can reduce current, reduce line loss, and improve energy transmission efficiency.

This makes the robot joint module more energy-efficient during operation, especially for heavy-duty robots, such as industrial handling robots. They need strong power to drive the joints to complete tasks such as heavy object handling. The 48V voltage can provide stronger power output, ensuring that the robot can operate stably under high-intensity work, while reducing the performance degradation caused by insufficient voltage.

Whether it is 24V or 48V, each has been strictly tested and optimized. According to different application scenarios and load requirements, they provide the most suitable "power heart" for our robot joint module, allowing the robot to complete tasks stably and efficiently in various complex environments.

HONPINE Differentiators: Voltage-Adaptive Engineering

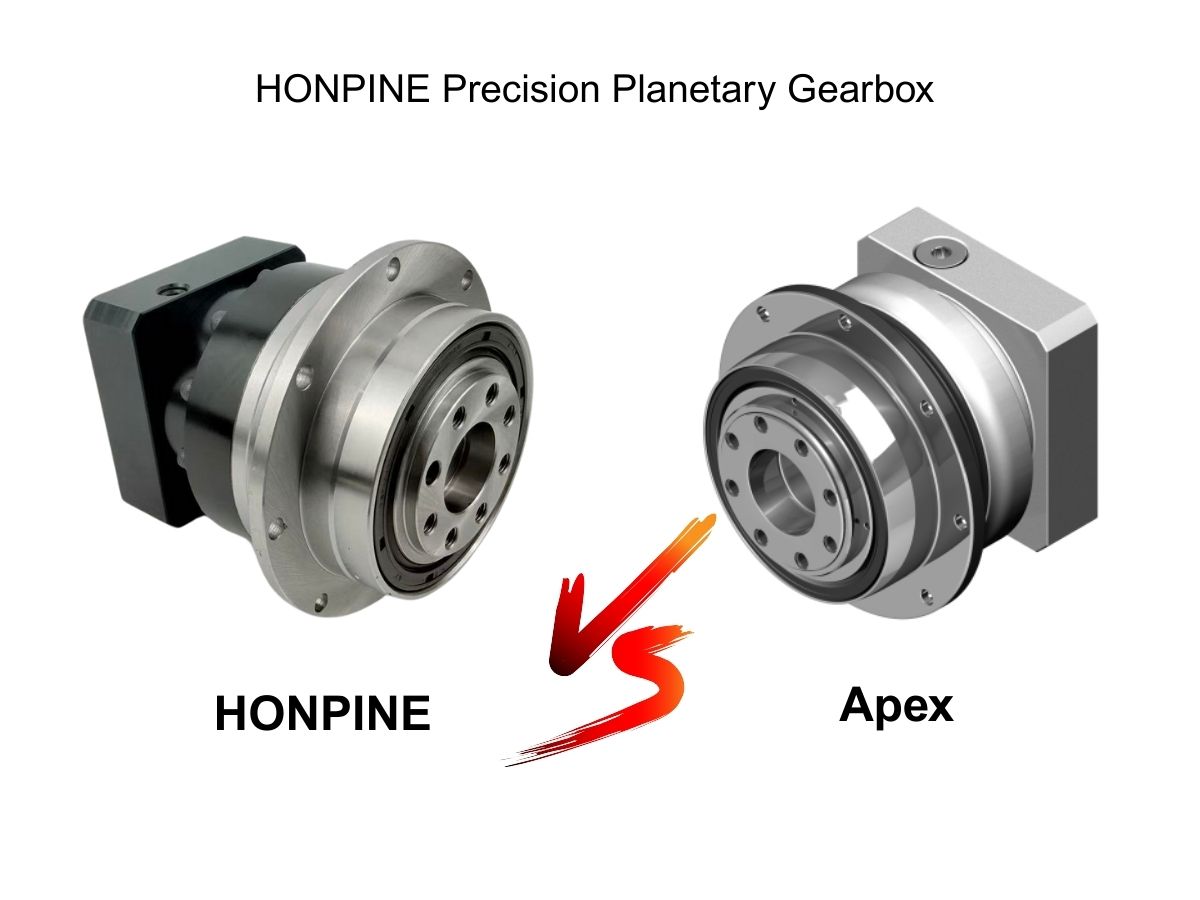

HONPINE joint modules have a wide range of interfaces and flexible installation methods, and can be adapted to different types of robot structures. Whether it is an industrial robot, a service robot, or a special robot, HONPINE joint modules can be quickly integrated into the system, providing convenience for the function expansion of the robot.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

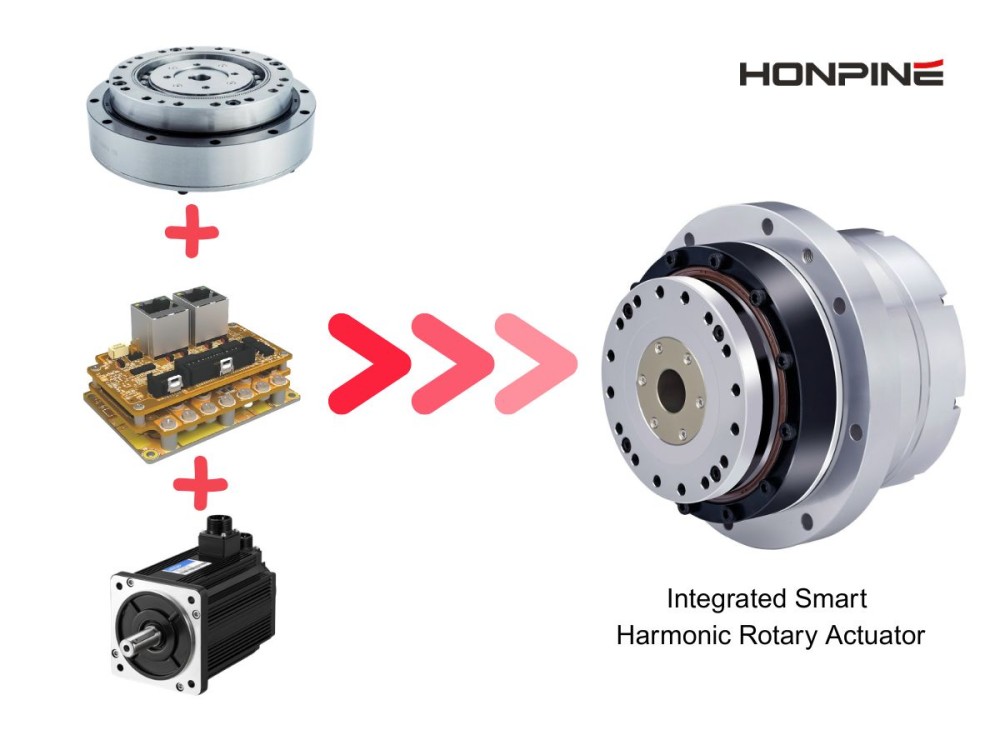

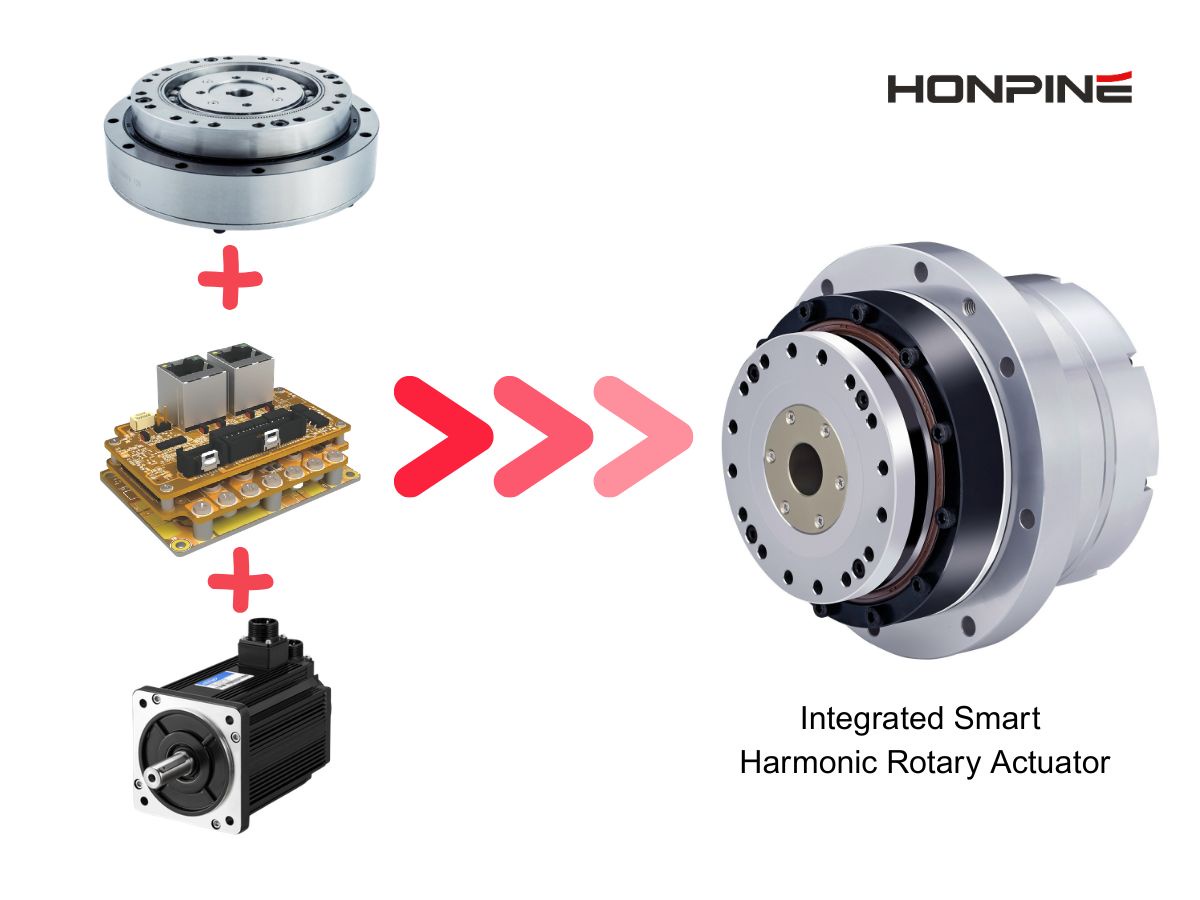

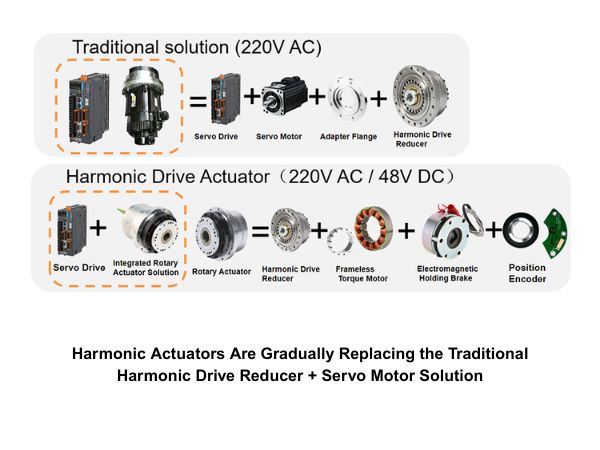

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand