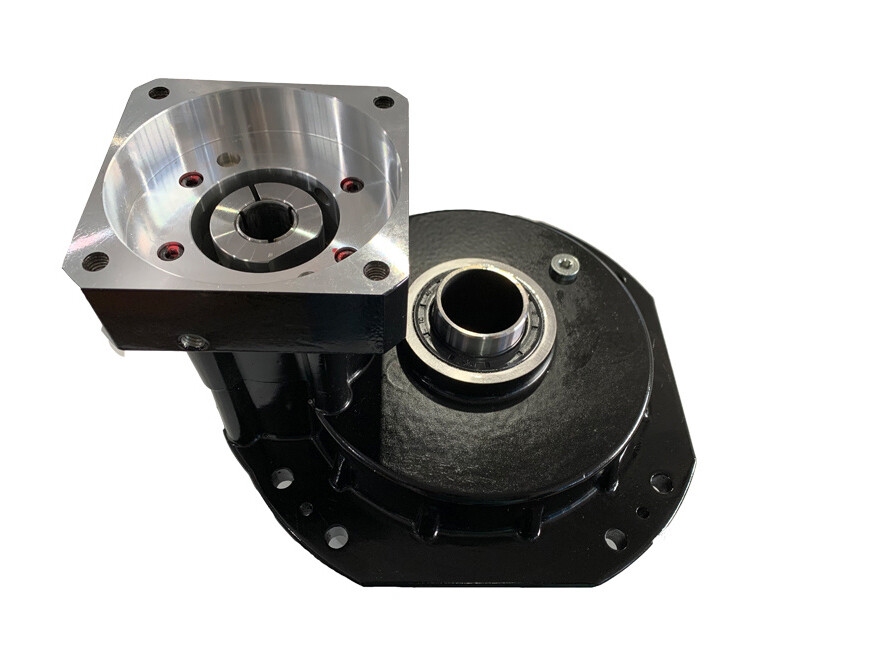

Hollow Output Shaft Flange Integrated Cycloid RV Robot Gearbox

● Introduction

In industrial robotics applications:

For robotic arms with end-effector loads ≤20kg, RV reducers are primarily used in base-to-high-load joints (typically Joints 1-4)

For robotic arms with end-effector loads >20kg, all six joints typically employ RV reducers

RV reducers serve as the core transmission component ensuring robotic arm positioning accuracy.

Application

Hollow output shaft design facilitates cable and piping routing, with factory-installed flange seals and pre-filled RV lubricant

● Two-stage reduction system:

Primary stage: Involute planetary gear transmission for initial speed reduction

Secondary stage: Cycloid pinwheel transmission for further speed reduction and torque stabilization

● Rigid impact-resistant structure:

a. Rigid disc support at output ensures even load distribution and minimizes deformation

b. Multi-crank shaft design with high-precision bearings effectively disperses stress impacts

● Compact enclosed layout:

Transmission mechanism integrated within planetary carrier support bearings significantly reduces axial dimensions

Features

● High load capacity and precision:

a. Torque range: 50-7000 N·m, suitable for heavy-duty robotic arms (welding, material handling, etc.)

b. Stable backlash precision (<1 arcmin) with minimal repeat positioning error

● Extended service life and reliability:

a. Multi-tooth meshing (≥30 teeth) ensures even wear distribution (service life: 6,000-10,000 hours)

b. Superior fatigue resistance compared to harmonic drives, ideal for 24/7 continuous operation

● High-efficiency transmission adaptability:

a. Transmission efficiency: 85%-95% with minimal energy loss

b. Wide reduction ratio range (31-203), adjustable through planetary gear tooth configuration

● Outstanding dynamic performance:

a. Low-vibration design ensures smooth robotic arm operation without end-effector jitter

b. Rapid acceleration response enables high-speed trajectory tracking

Specification

Sheet 1