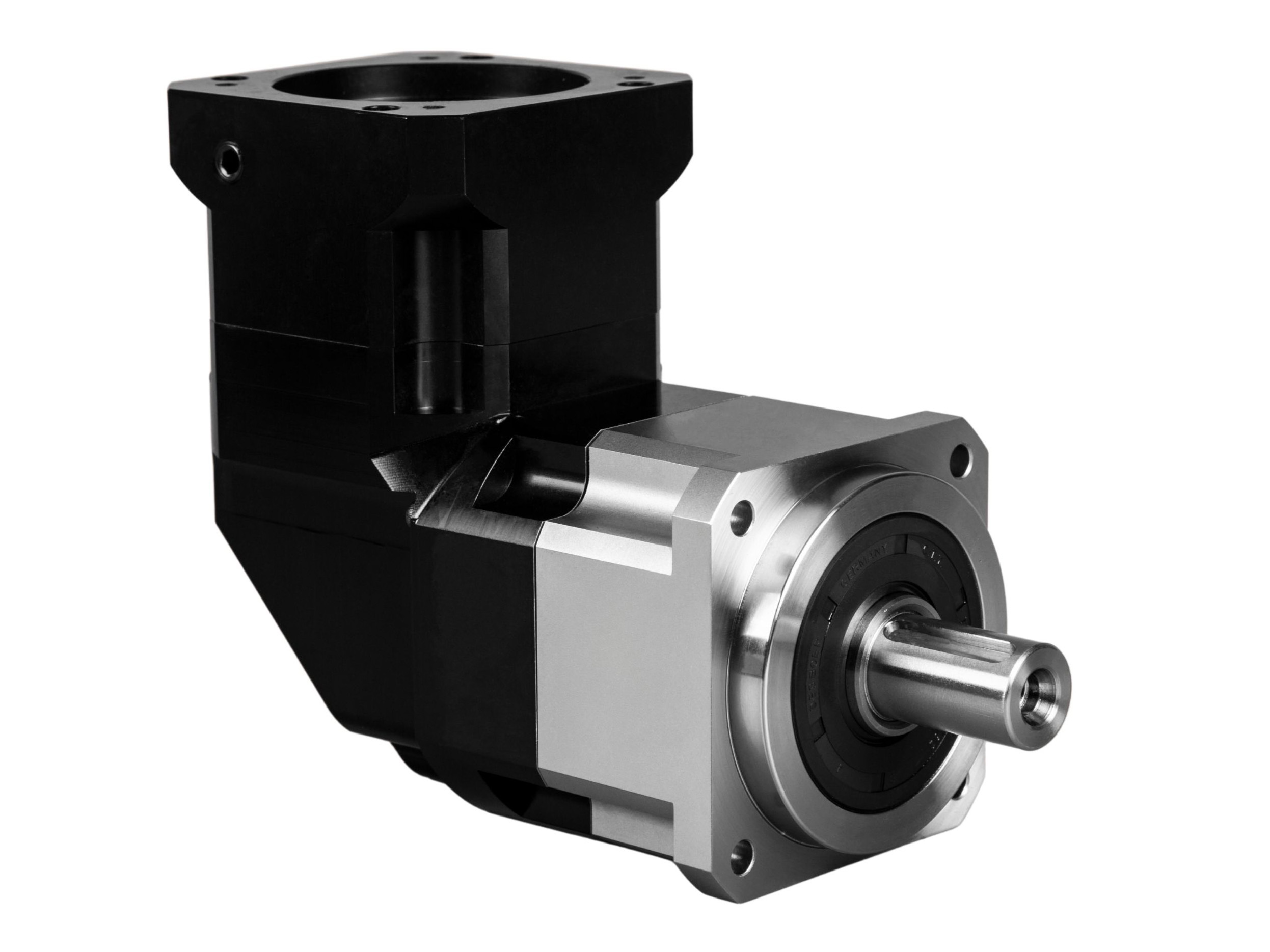

Right Angle Square Housing Output Flange Planetary Reducer

● Introduction

Features

● Square Housing and Output Flange

The reducer housing and output flange feature a square structure. Screws are fastened from the bottom upward, securing the unit to the mounting structure.

● 90 Degree Input Output Orientation

The input and output shafts are oriented at 90 degrees, saving space and altering the output direction.

● High-Efficiency Helical and Bevel Gears

All gears utilize helical teeth, with an integrated bevel gear set, ensuring high transmission efficiency. Multi-stage transmission maintains over 90% efficiency.

● High Precision and Low Backlash

Precision gear grinding processes and a collet-style locking mechanism minimize backlash to within 2 arcminutes (1/30 of a degree), meeting the stringent positioning accuracy demands of servo systems.

● High Load Capacity

A multi-tooth meshing design distributes loads evenly. Combined with carburized and quenched gears and needle roller bearings, the reducer delivers output torque up to several thousand Nm and exceptional impact resistance.

● Noise Reduction and Stability

A patented noise-reduction structure and helical tooth surface rolling meshing design significantly reduce operational noise while ensuring smooth operation without vibration.

● Durability and Maintenance-Free Design

Premium seals and lifetime lubrication technology extend gear service life beyond 20,000 hours. The reducer withstands harsh operating conditions, including high temperatures and dusty environments.

Specification

Sheet 1

Sheet 2