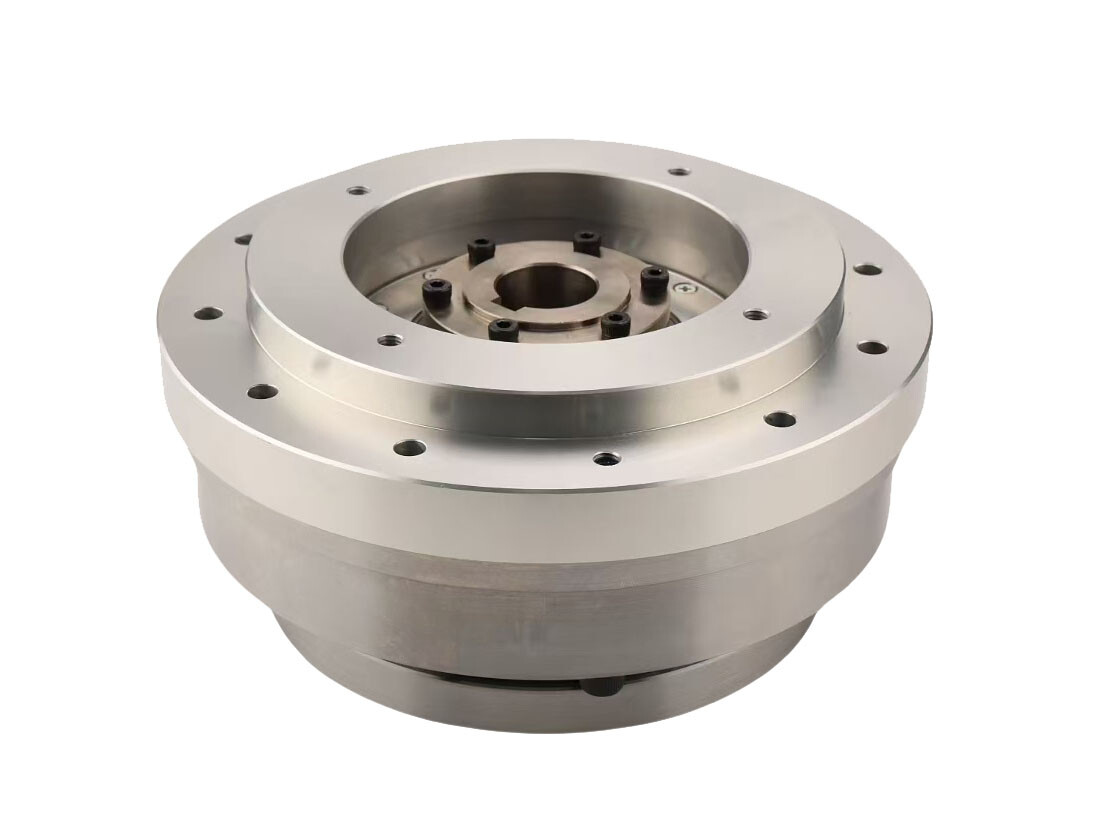

High Rigidity Motor Shaft Flange Harmonic Drive Reducer

● Introduction

The LHSG-RDP series harmonic drive reducer is developed on the high-rigidity FHG-I platform to accommodate customers requiring direct motor integration. It incorporates pre-machined motor shaft connection holes and motor mounting flanges, with the gear unit factory-sealed with specialized lubricating grease. This series typically adopts a fixed flexspline end and an output circular spline end directly coupled to the motor during operation. It offers exceptional convenience for applications demanding both direct motor connection and enhanced harmonic drive rigidity – customers can achieve immediate usability by simply aligning the motor shaft and tightening the fasteners post-purchase. This design optimizes installation efficiency while maintaining structural robustness for high-stiffness direct-drive scenarios.

Contact Us

Features

● Integrated with motor shaft and flange, featuring pre-machined motor connection holes based on the FHG series platform

● Significantly simplifies customer integration by eliminating custom flange manufacturing requirements

● Provides superior rotational accuracy and repeatable positioning performance

● Coaxial input/output shaft alignment

Specification

Sheet 1

Sheet 2

Sheet3

Download(3D /PDF)