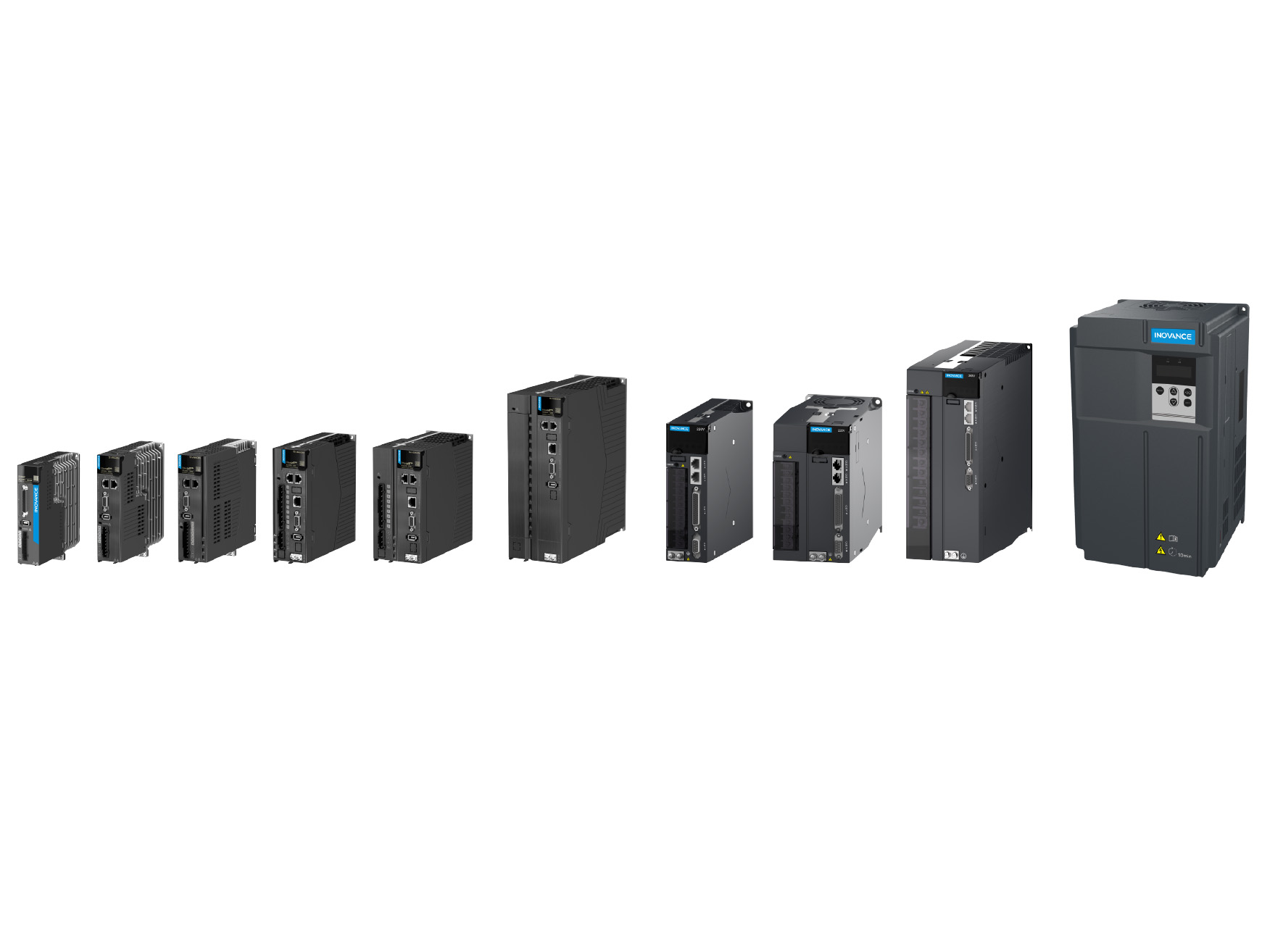

Servo Drive for High Precision Speed Torque Rotary Actuators

● Introduction

Application

Modular design integrating high-precision encoders and intelligent power modules (IPM), offering compact size and strong EMI resistance.

Supports multiple control modes (position/speed/torque) and is compatible with both AC permanent magnet synchronous motors and DC servo motors.

● Control Algorithm

Vector-based triple-loop control (current/speed/position) optimizes dynamic response accuracy and stability.

Implements complex control logic via digital signal processors (DSPs), supporting networked communication and remote debugging.

● Performance Highlights

Micron-level positioning: High-resolution encoder feedback eliminates cumulative errors, achieving sub-micron repeatability.

Rapid response: Low electromechanical time constant enables millisecond-level start/stop or direction reversal, ideal for high-frequency motion.

Wide speed range: Supports low-speed high-torque and high-speed light-load operation, with a speed ratio exceeding 1:5000.

● Adaptability

Compatible with standard interfaces (e.g., EtherCAT, CANopen) for seamless PLC/system integration.

Built-in soft-start circuits and overvoltage/overcurrent protection reduce startup surges and failure risks.

Features

● High-efficiency control

Torque-dense design and regenerative braking achieve >90% energy efficiency.

● Superior dynamic performance

Full digital control enables <1ms response times for complex motion planning.

● Safety redundancy

Dual closed-loop verification (encoder + sensor) and fault self-diagnostics ensure reliability.

● Environmental resilience

High-temperature components and dust-resistant coatings support operation from -20°C to 70°C.