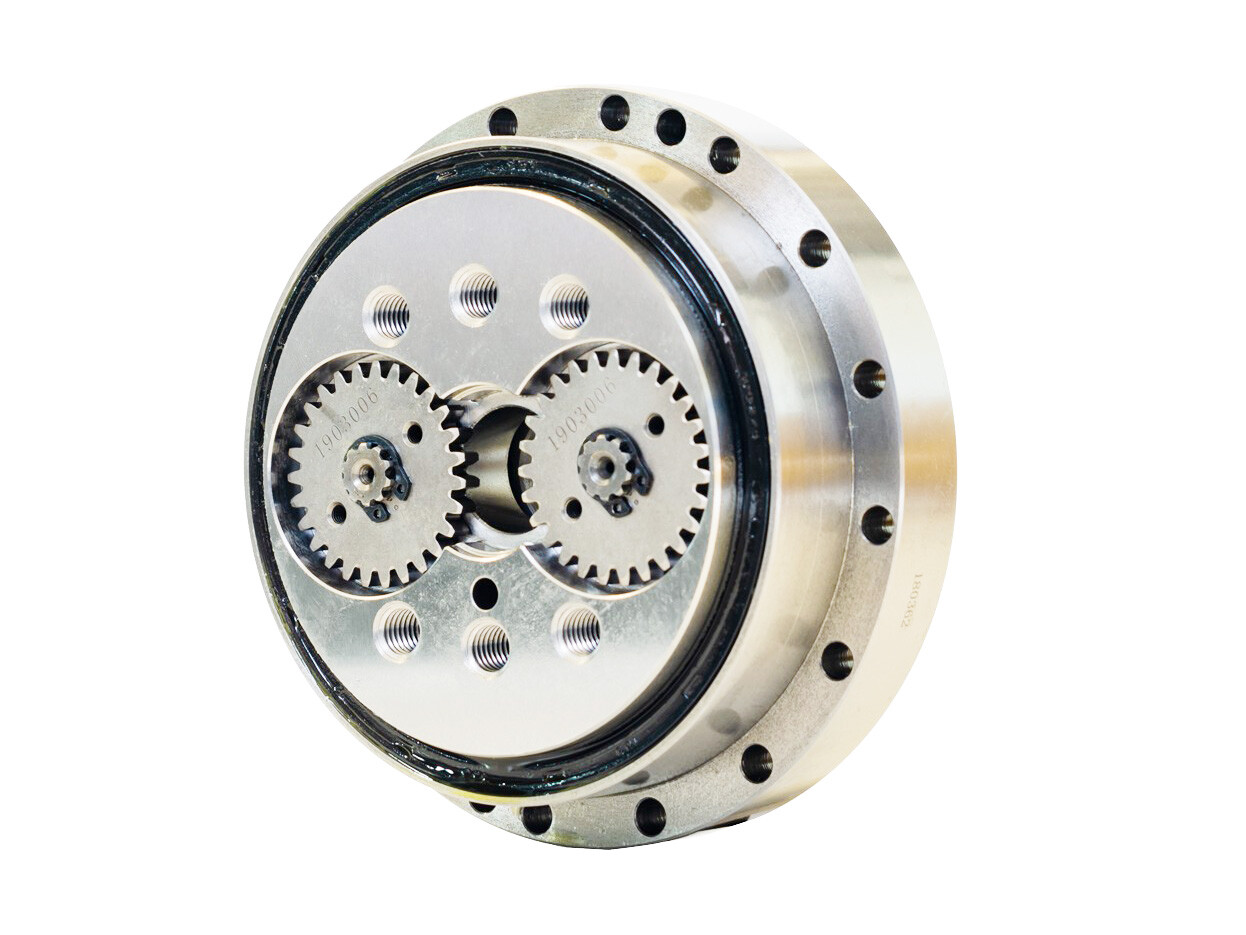

Solid Output Shaft Planetary Gear Transmission RV Reducer for Heavy Duty Robotic Arms

● Introduction

For robotic arms with end loads ≤20 kg, RV reducers are primarily employed in base-to-high-load joints (typically Joints 1-4).

For robotic arms with end loads >20 kg, all six joints typically utilize RV reducers.

RV reducers serve as the core transmission component ensuring robotic arm positioning accuracy.

Application

Enables direct load coupling and provides enhanced sealing convenience.

● Two-Stage Reduction Design

First Stage: Involute planetary gear transmission for initial speed reduction.

Second Stage: Cycloid pinwheel transmission for further speed reduction and torque stabilization.

● High Rigidity & Impact Resistance

Rigid disc support at the output ensures uniform load distribution, minimizing deformation.

Multi-crank shafts combined with high-precision bearings effectively disperse stress impacts.

● Compact Enclosed Structure

The transmission mechanism is integrated within the planetary carrier support bearings, significantly reducing axial dimensions.

Features

● High Load Capacity & Precision

Torque range: 50–7000 N·m, suitable for heavy-duty robotic arms (e.g., welding, material handling robots).

Backlash precision: <1 arcmin, with minimal repeat positioning error.

● Long Lifespan & High Reliability

Multi-tooth meshing (≥30 teeth) ensures even wear distribution, extending service life to 6,000–10,000 hours.

Superior fatigue resistance compared to harmonic drives, making it ideal for 24/7 continuous operation.

● High Efficiency & Adaptability

Transmission efficiency: 85%–95%, minimizing energy loss.

Wide reduction ratio range (31–203), adjustable via planetary gear teeth configuration.

● Exceptional Dynamic Performance

Low-vibration design guarantees smooth robotic arm operation, eliminating end-effector jitter.

Rapid acceleration response, enabling high-speed trajectory tracking.

Specification

Sheet 1