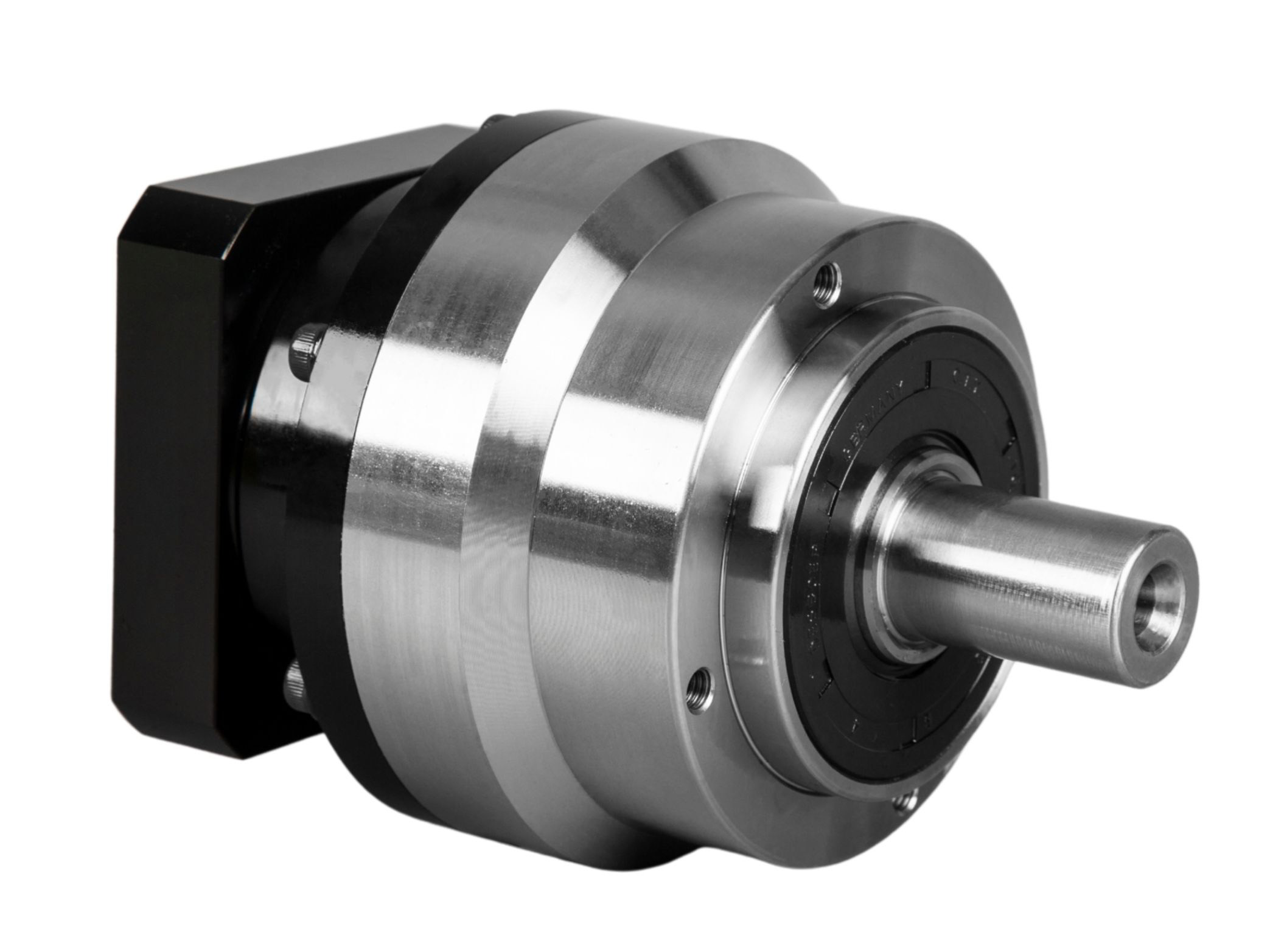

Circular Flange high precision Reduction Planetary Gearbox

● Introduction

Features

The gearbox housing and output flange adopt a circular structure. Screws are fastened vertically downward from the top, and additional flanges can be customized on the circular output end to meet specific customer requirements.

● 90-Degree Input-Output Configuration

The perpendicular shaft arrangement optimizes space utilization and redirects output torque.

● High-Efficiency Helical and Bevel Gears

Utilizes helical gears combined with an integrated bevel gear set, maintaining over 90% efficiency in multi-stage transmission.

● Ultra-High Precision and Low Backlash

Precision ground gears and a collet-style locking mechanism minimize backlash to ≤2 arcminutes (1/30 of a degree), meeting servo systems' stringent positioning accuracy demands.

● Exceptional Load Capacity

Multi-tooth meshing design evenly distributes loads. Carburized and quenched gears paired with needle roller bearings deliver output torque up to several thousand Nm and outstanding impact resistance.

● Noise Reduction and Vibration-Free Stability

Patented noise-reduction architecture and helical tooth rolling meshing technology reduce operational noise to minimal levels while ensuring smooth, vibration-free performance.

● Extended Durability and Zero Maintenance

Premium seals and lifetime lubrication technology ensure a gear service life exceeding 20,000 hours, even in extreme environments with high temperatures or heavy dust exposure.