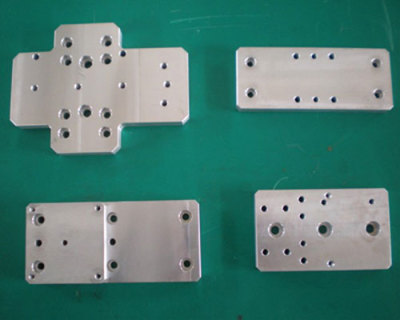

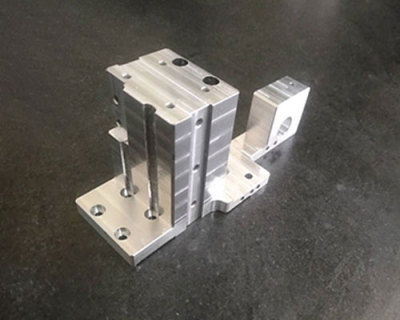

High Precision Machined Aluminum Alloy Parts

● Introduction

Customized processing technology

Characteristics

Lightweight

Aluminum has a density of approximately 2.7 g/cm³, which is much lower than many common metals such as iron (about 7.86 g/cm³) and copper (about 8.96 g/cm³). This gives precision aluminum parts a clear advantage in weight-sensitive applications, such as aerospace and automotive industries.

High Strength-to-Weight Ratio

Through proper alloying and heat treatment, aluminum alloys can achieve high strength. Their strength-to-weight ratio is superior to that of many traditional metal materials, allowing structural strength to be maintained while significantly reducing component weight.

Excellent Corrosion Resistance

Aluminum readily reacts with oxygen in the air to form a dense aluminum oxide film on its surface. This oxide layer prevents further oxidation of the underlying material, giving aluminum good corrosion resistance and making it suitable for harsh working environments.

Good Thermal and Electrical Conductivity

Aluminum has excellent thermal and electrical conductivity. In electrical and electronic industries, precision aluminum parts are often used for components such as wires, cables, and heat sinks that require efficient heat dissipation and electrical performance.

Good Machinability

Aluminum has relatively low hardness and is easy to machine through cutting, drilling, stamping, forging, and other processes. It can be manufactured into complex shapes with high precision using various machining methods, offering high efficiency and relatively low processing costs.

Recyclability

Aluminum is highly recyclable. The energy required for recycling aluminum is only about 5% of that needed for primary aluminum production, with minimal loss of material properties. Precision aluminum parts can therefore be recycled and reprocessed, supporting environmental protection and sustainable development.

Machining Processes

Cutting Machining

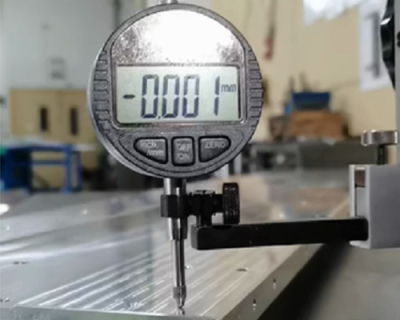

Includes turning, milling, drilling, and boring. High-precision machining equipment and cutting tools are used to process aluminum alloy blanks to achieve the required shape and dimensional accuracy. To ensure machining precision and surface quality, appropriate cutting parameters—such as cutting speed, feed rate, and depth of cut—must be selected, along with suitable cutting fluids for cooling and lubrication.

Grinding Machining

Used for fine surface finishing of precision aluminum parts to achieve higher surface smoothness and dimensional accuracy. Grinding is typically performed after cutting operations and includes surface grinding, external cylindrical grinding, and internal cylindrical grinding, depending on part requirements.

Electrical Discharge Machining (EDM)

For precision aluminum parts with complex shapes that are difficult to machine using conventional cutting methods, EDM can be employed. This process removes material through high-temperature melting and vaporization generated by pulsed electrical discharges, enabling the machining of intricate features.

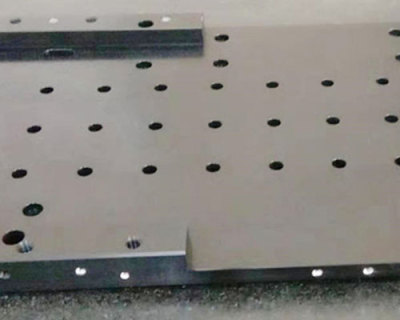

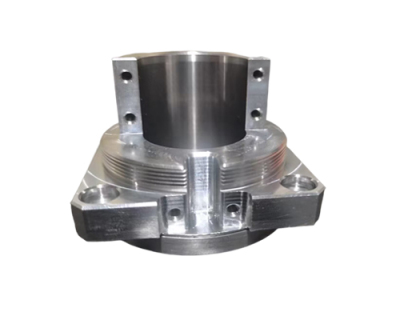

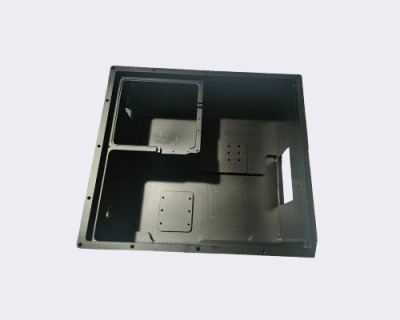

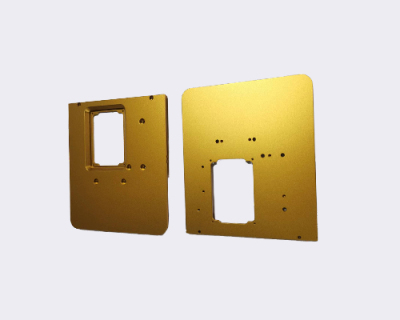

Custom Precision Aluminum Parts

We are capable of manufacturing precision aluminum parts with complex cavities, narrow slots, and other intricate structures while maintaining high machining accuracy.

Precision Forging

Precision forging involves heating and pressurizing aluminum alloy billets to induce plastic deformation within a mold, producing parts with the required shape and dimensions. This process improves the internal structure of the aluminum alloy, enhancing strength and toughness, while achieving high dimensional accuracy and surface quality. It also reduces subsequent machining allowances and improves production efficiency.

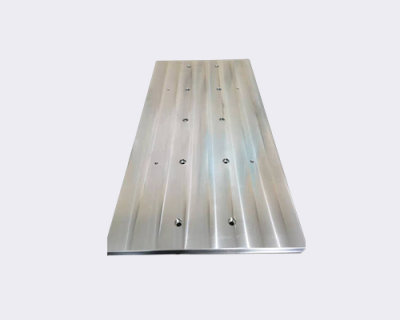

Surface Treatment

To further enhance corrosion resistance, wear resistance, and aesthetic appearance, precision aluminum parts typically undergo surface treatment. Common methods include anodizing, electroplating, electroless plating, and coating. For example, anodizing forms a hard, wear-resistant, and corrosion-resistant oxide layer on the aluminum surface, extending service life and allowing various colors to be achieved through dyeing to meet decorative requirements.

Application Fields

Aerospace Industry

Used in the manufacture of aircraft wings, fuselage structural components, and engine parts. Components such as spars, frames, and flaps made from precision aluminum parts help reduce aircraft weight while maintaining structural strength and reliability, improving fuel efficiency and flight performance.

Automotive Industry

Widely applied in engines, transmissions, chassis, and body components. Aluminum alloy engine blocks, cylinder heads, and pistons reduce engine weight and improve fuel economy. Precision aluminum alloy wheels are not only aesthetically pleasing but also reduce unsprung mass, enhancing vehicle handling performance.

Electronics and Electrical Industry

An important material for electronic device housings, heat sinks, and circuit boards. Precision aluminum enclosures for products such as computers and smartphones provide excellent heat dissipation, mechanical strength, and a lightweight, attractive appearance. In circuit board manufacturing, aluminum-based copper-clad laminates offer good thermal and electrical performance for high-power electronic devices.

Precision Machinery Industry

Used to manufacture components for precision instruments and equipment, such as machine tool worktables, guide rails, and measurement instrument brackets. The high stability and good machinability of aluminum alloys ensure high accuracy and reliability, meeting the strict requirements of precision machinery.

Medical Device Industry

Also widely used in medical devices, including surgical instruments, equipment housings, and support structures. Precision aluminum parts are lightweight, corrosion-resistant, and non-magnetic, ensuring they do not interfere with medical equipment performance while facilitating ease of operation for medical professionals.