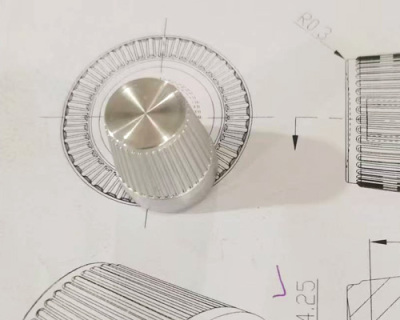

Custom Metal Parts for Four-Axis CNC Machine Tools

● Introduction

Customized processing technology

A four-axis machining center can reduce the number of workpiece setups, minimizing positioning errors caused by multiple clamping operations and improving machining accuracy. When high positional accuracy is required between different machining features of a part, a four-axis machining center can complete all features in a single setup, avoiding positioning errors from repeated clamping and ensuring the required positional accuracy.

At the same time, four-axis machining centers commonly adopt semi-closed-loop or even fully closed-loop position compensation systems, providing high positioning accuracy and repeatability. Dimensional errors generated during machining can be compensated for in real time, resulting in higher dimensional accuracy compared with conventional machine tools. In addition, four-axis machining centers can reduce auxiliary time for loading and unloading workpieces, save a large amount of special and general tooling, and lower overall production costs.

Due to the high rigidity and power of four-axis machining centers, larger cutting parameters should be selected whenever possible during machining to reduce processing time. However, the resulting temperature rise may affect machining accuracy. Therefore, it is essential to select appropriate cutting tools and fixtures and ensure sufficient cooling during processing.

Process Planning and Machining Sequence

Machining processes should be arranged reasonably by determining the processing sequence of the parts, including machining reference surfaces, datum holes, and machining allowances. When determining the operations to be completed in a single setup, the final accuracy requirements and heat treatment requirements of the part must be considered. For some complex parts, due to factors such as thermal deformation, internal stress, and clamping deformation during machining, it may be necessary to complete the machining in two or more setups.

The machining sequence should follow the principle of progressing from rough to finish machining. First, heavy cutting and rough machining are performed to remove most of the machining allowance from the blank. Then, machining operations with lower heat generation and lower accuracy requirements are arranged, allowing sufficient cooling time before finishing. Finally, finishing operations are carried out. Each process should minimize idle tool movements and reduce tool change frequency as much as possible.

The recommended machining sequence is as follows:

rough and finish milling of large planes → rough boring → finish boring → vertical milling → center drilling → drilling → tapping → hole and surface finishing (reaming, boring, finish milling, etc.).