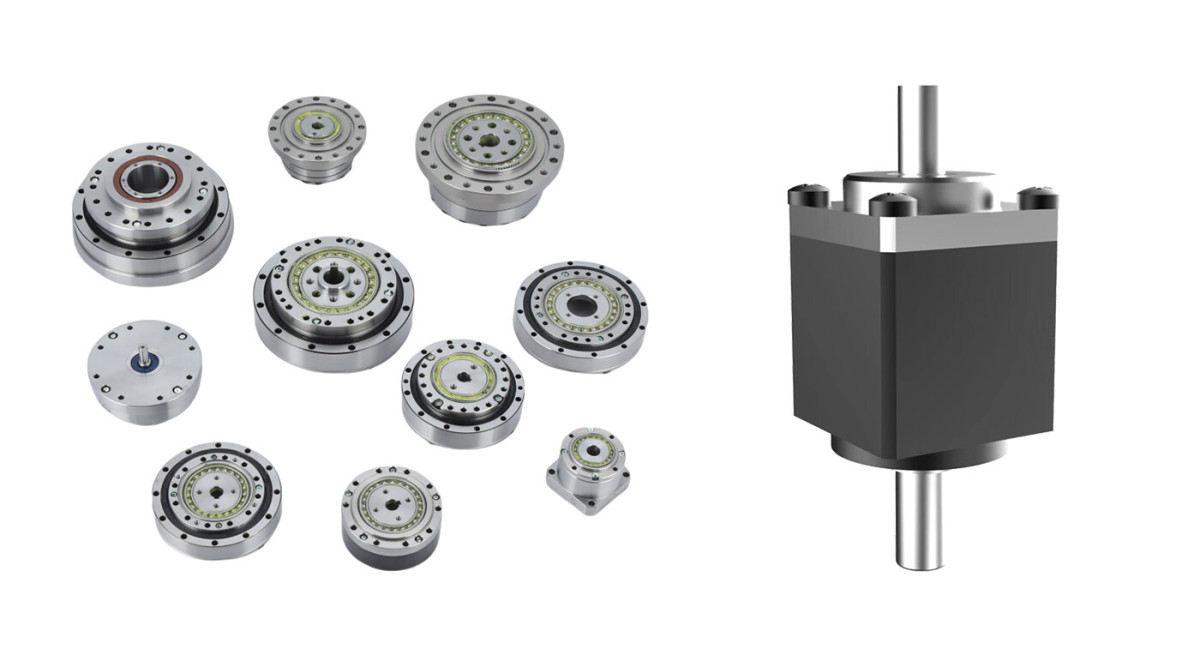

The Precision Gearbox Behind Five-Axis CNC Machining: RV Gearbox Reducers, Harmonic Drive Reducers

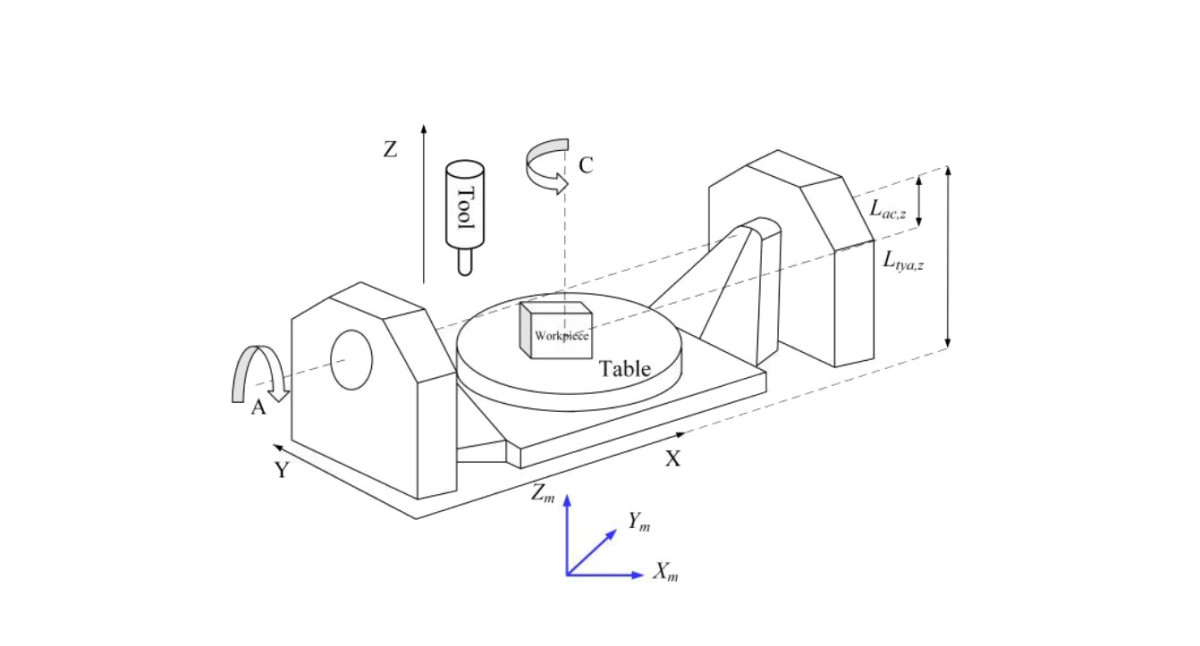

Five-axis CNC machining is a multi-axis CNC machining method that adds two rotational axes (any combination of A, B, and C axes) to the three basic linear coordinate axes (X, Y, and Z). The synchronized movement of all five axes (three linear and two rotational) is called five-axis linkage machining. When the two rotational axes are positioned to maintain a fixed tool orientation angle while the three linear axes move, this machining method is called five-axis positional machining. The five-axis rotary table is the core component for implementing five-axis CNC machining technology. The precision gearbox can convert the servo motor's high-speed, low-torque output into low-speed, high-torque motion to meet cutting load requirements. The multi-stage gear structure of the RV reducer gearbox can withstand heavy-load cutting impacts and reduce vibration. The harmonic drive reducer achieves zero-backlash transmission through elastic deformation or preload structures to ensure positioning accuracy.

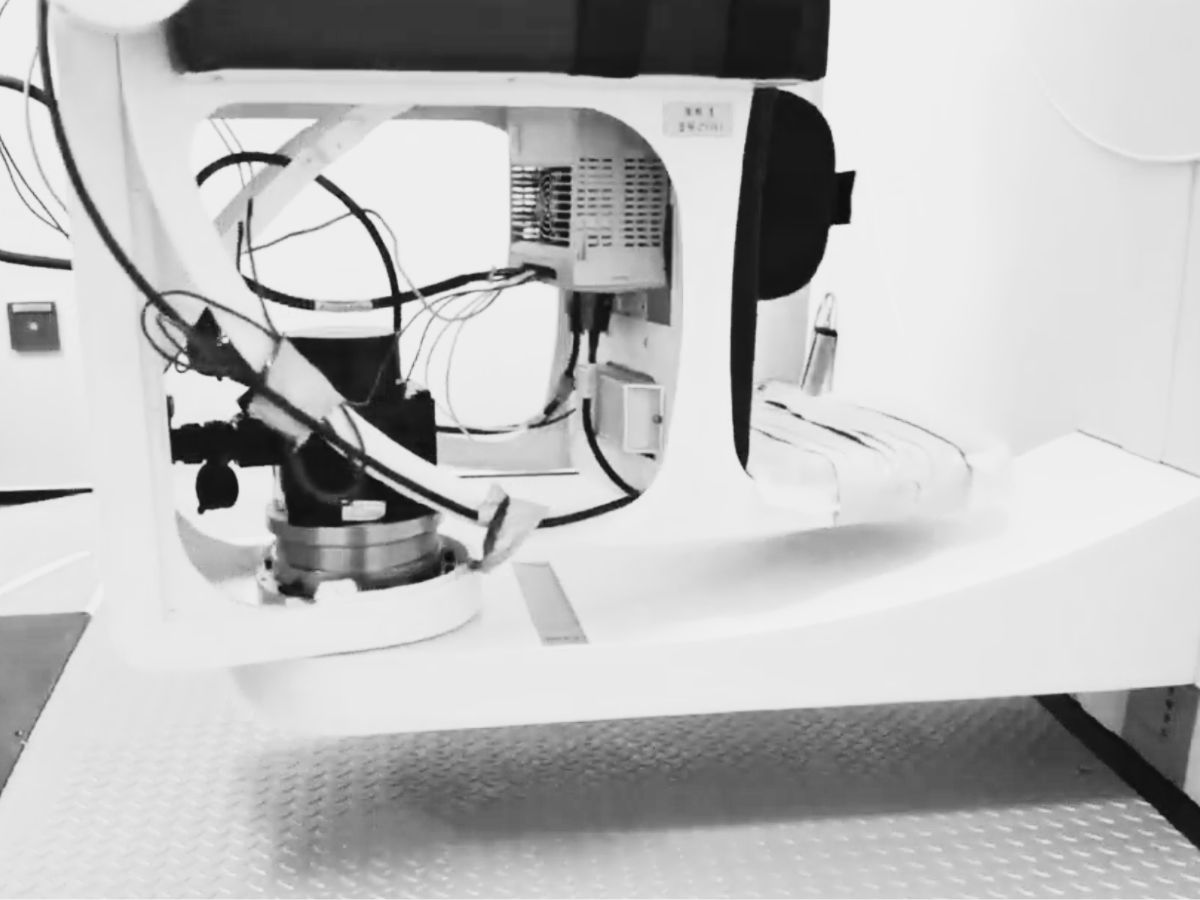

Application of RV reducer gearboxes in five-axis rotary table machine tools:

The RV reducer gearbox is often used to drive the C-axis and B-axis due to its high rigidity, high torque capacity, and long service life. The RV reducer gearbox ensures stability and high precision during heavy-load cutting. In some high-end manufacturing fields, the performance of the RV reducer gearbox determines the processing limits of the machine tool, such as in aircraft engine blade machining.

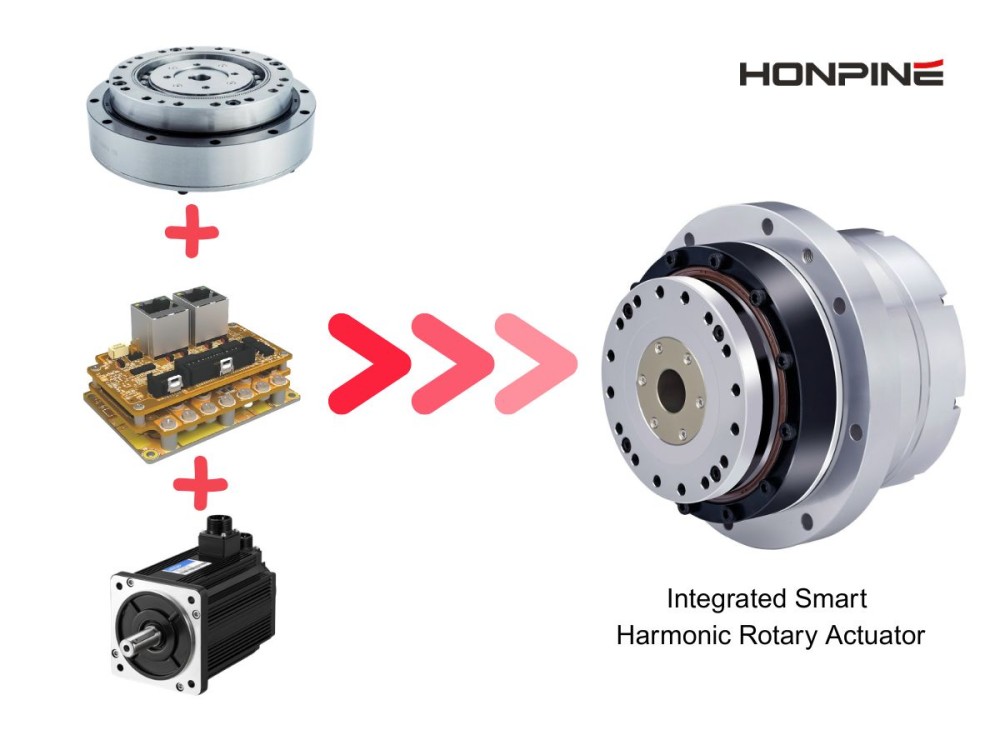

Application of harmonic drive reducers in five-axis rotary tables:

The harmonic drive reducer is often used in the A/C axis of five-axis rotary tables due to its zero backlash, high precision, compact and lightweight design, and high transmission efficiency. In some lightweight five-axis machine tools, it is also used for the B axis, such as in five-axis engraving and milling machines and medical equipment processing machines. Machining accuracy is an important indicator for measuring CNC machine tool performance. Due to its high precision and lightweight characteristics, the harmonic drive reducer has become an indispensable choice in precision processing fields such as medical, optical, and 3C industries.

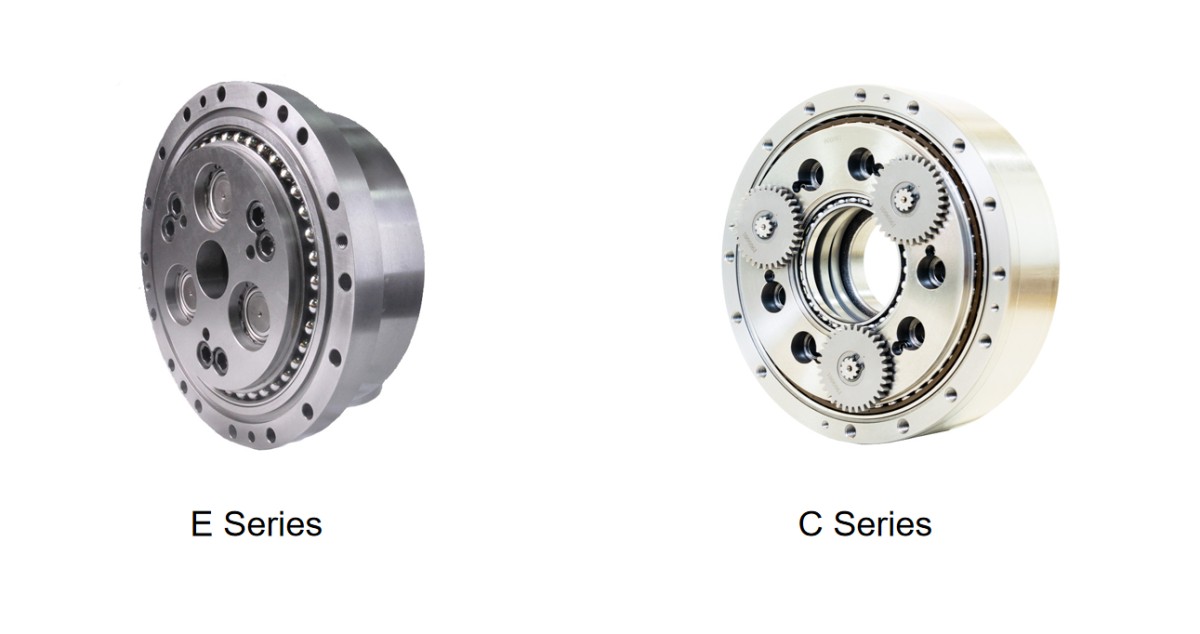

Differences of Harmonic Drive Reducer and RV Gear Reducer

Precision reducer gearboxes are the core transmission components of five-axis rotary tables, which directly affect the machining accuracy, dynamic response, and load capacity of machine tools. RV reducer gearboxes and harmonic drive reducers respectively dominate in heavy-duty and precision transmission applications. The two are often used together to implement hybrid drive solutions for high-end CNC machine tools.

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand