RV reducers, harmonic drive reducers, and planetary reducers help Construction Robot to operate efficiently

With advancements in AI, IoT, big data, sensors, and BIM technologies, the construction industry is transitioning from traditional manual/semi-automated methods toward full automation, intelligence, and data-driven operations. Intelligent construction has now become the dominant trend, where construction robots significantly accelerate project timelines and are essential for industry-wide quality enhancement. As critical components ensuring robotic precision and stability, harmonic drives reducer, RV reducers, andplanetary gearbox perform distinct roles across various robot subsystems.

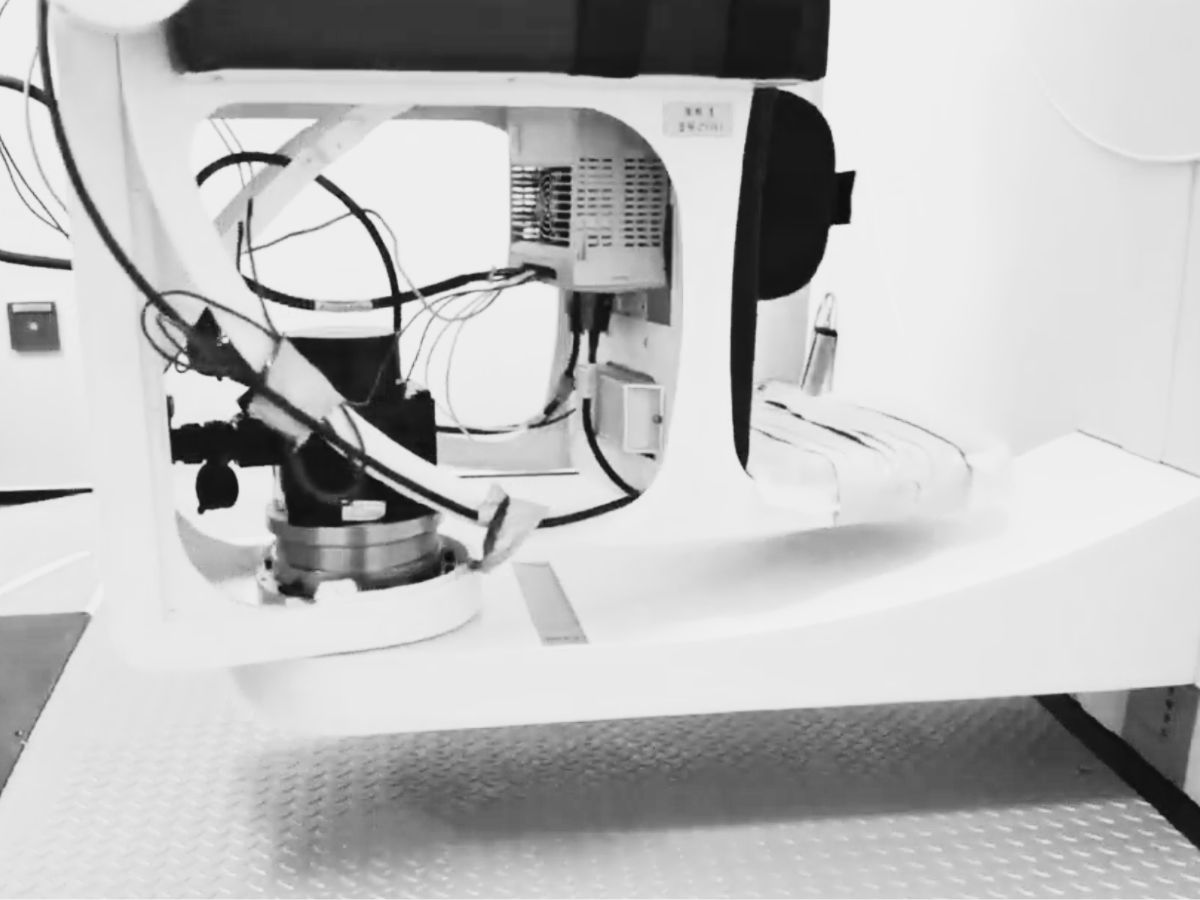

Welding Robots

Welding robots guarantee structural integrity through millimeter-accurate welding, far exceeding manual capabilities. Their closed-loop control of motion trajectories combined with stable current/voltage output ensures consistent weld quality. Equipped with machine vision and sensors, these robots dynamically adjust welding parameters and paths while detecting defects in real-time – particularly vital for large-scale structures where they operate safely in confined or elevated spaces inaccessible to humans.

Spraying Robots

Spraying robots achieve uniform coating thickness through precision control of nozzle velocity, spray angle, and flow rate – reducing material waste by 15-30% (industry data). In human-robot collaboration, operators program parameters (pressure/flow/speed) and map worksites via BIM. Autonomous robots then navigate complex surfaces (walls/ceilings/beams), dynamically adapting to material textures and paint viscosity.

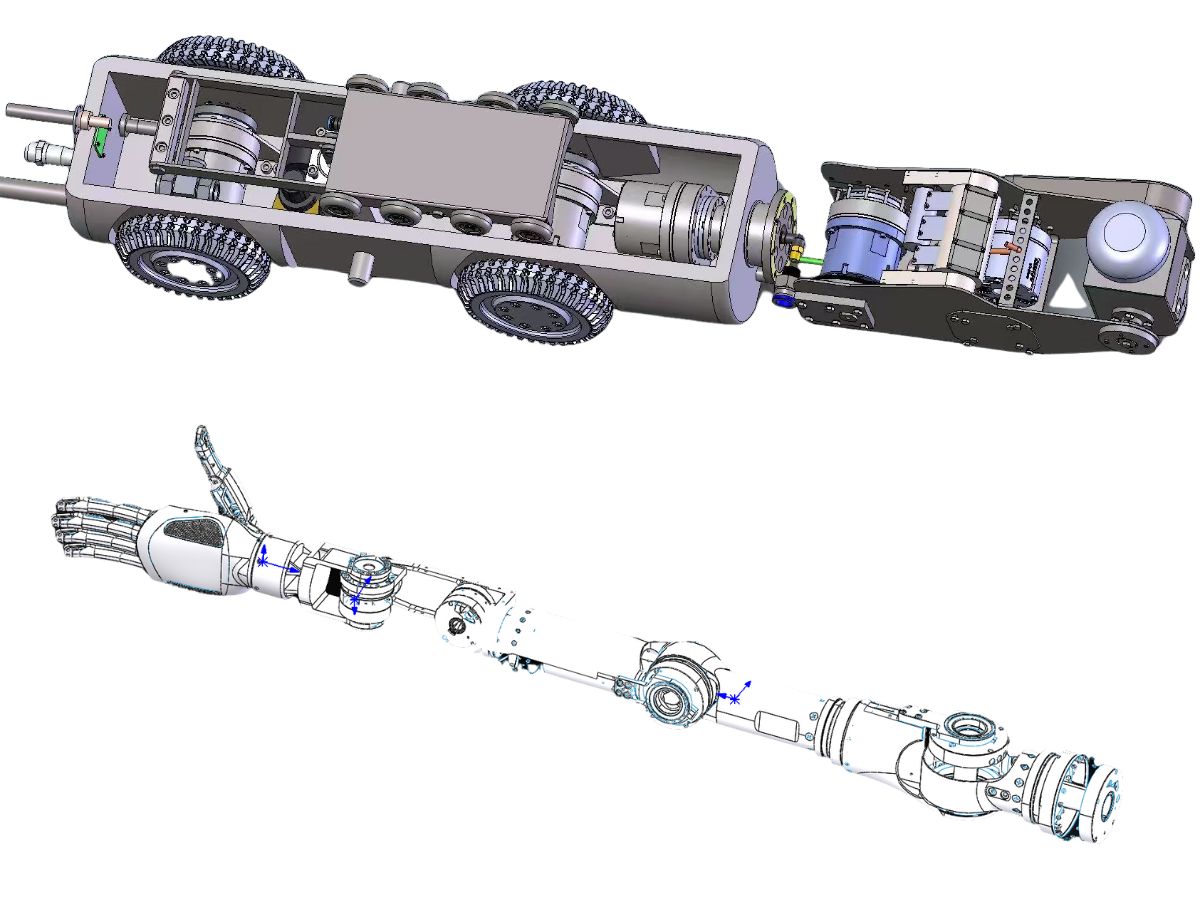

Concrete Robots

Concrete robots automate batching (precision mix-ratio control), transport (just-in-time delivery), and pouring. Advanced units feature:

Pump systems enabling continuous pour uniformity

Embedded sensors monitoring concrete slump and placement thickness

Crack-prevention thermal management during mass pours

Articulated arms reaching congested rebar zones

HONPINE: Precision Reducer Partner for Construction Robotics

Since 2018, we have delivered mission-critical reducers for:

Welding/Spraying/Concrete Robots

Niche applications: Terrain Leveling | Rebar Tying | Robotic Masonry

Serving 20+ Tier-1 construction robotics OEMs (confidentiality upheld), we provide:

✓ Application-specific reducer selection

✓ Dynamic load simulation services

✓ Dedicated technical account management

Contact HONPINE for:

Customized reducer solutions

Field failure mode analysis (FMEA) reports

Lifecycle maintenance programs

Read More

Learn more about the story of HONPINE and industry trends related to precision transmission.

Double Click

We provide harmonic drive reducer,planetary reducer,robot joint motor,robot rotary actuators,RV gear reducer,robot end effector,dexterous robot hand