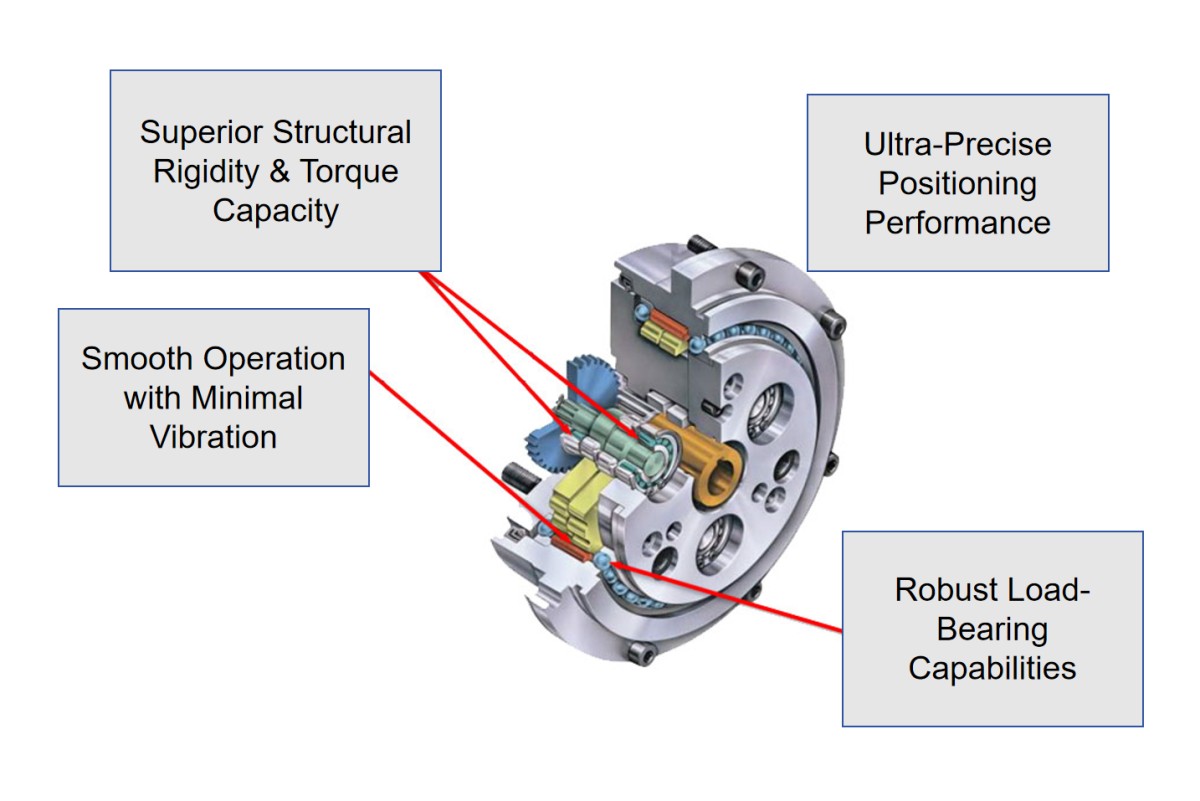

Using RV reducers with high precision, rigidity, and reliability as the underlying support can improve the market competitiveness of welding machinery. Choosing a robot arm with HONPINE RV reducer can help improve welding quality and extend the service life of the machinery.

What are the advantages of using HONPINE RV reducer?

Improved positioning accuracy

Ordinary reducers may produce an error of about ±1°, while HONPINE RV reducers can achieve high-precision control within ±0.01°. This enables the equipment to meet micron-level position adjustment requirements during welding and CNC processing. Combined with HONPINE high-resolution encoders, micron-level motion control can be achieved to meet the stringent requirements of laser welding and precision spot welding.

Stable rotation control

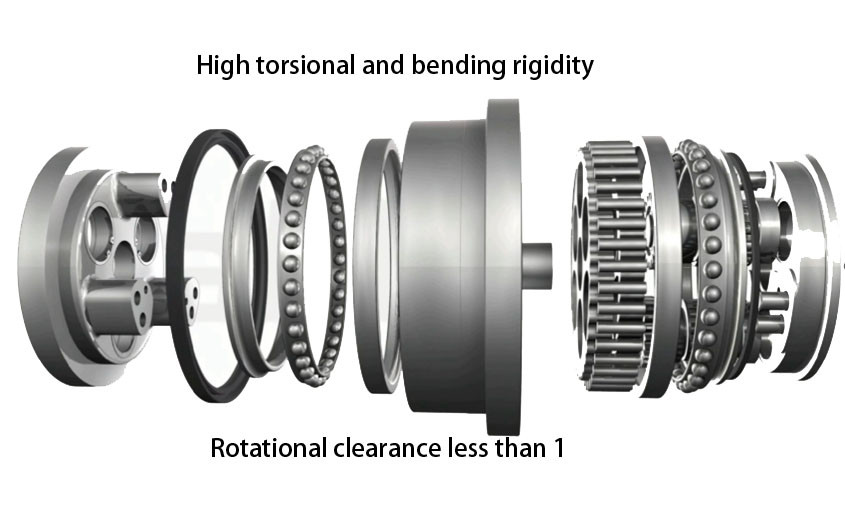

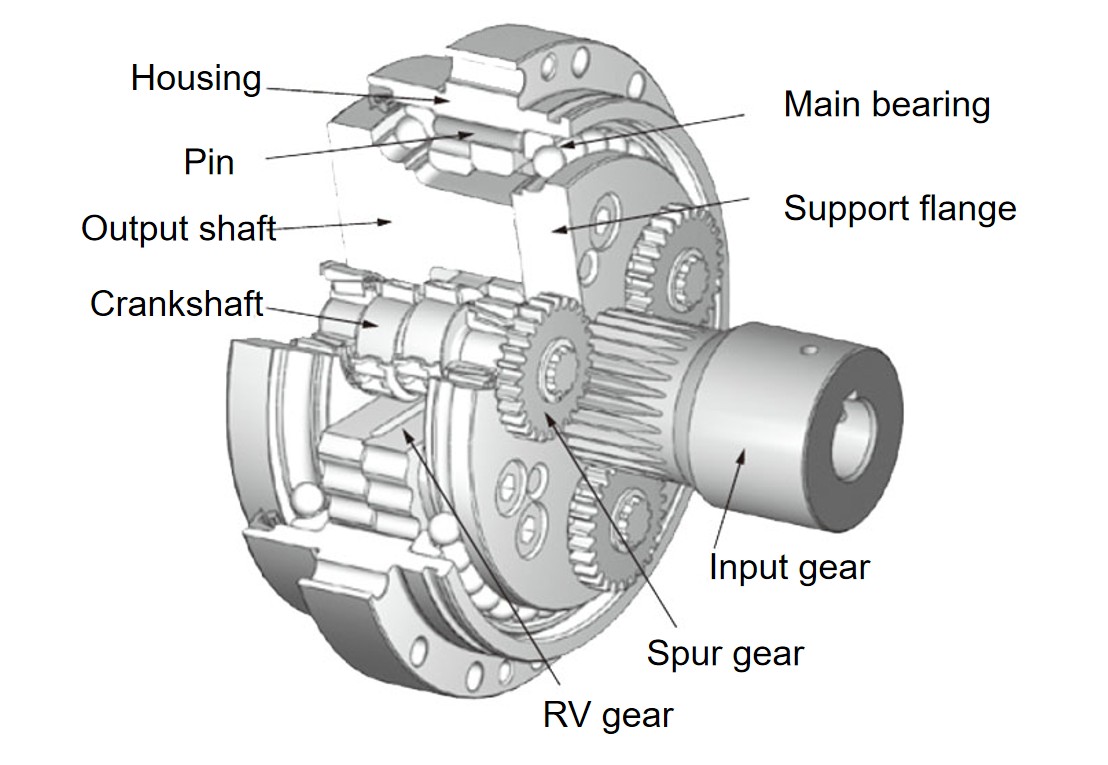

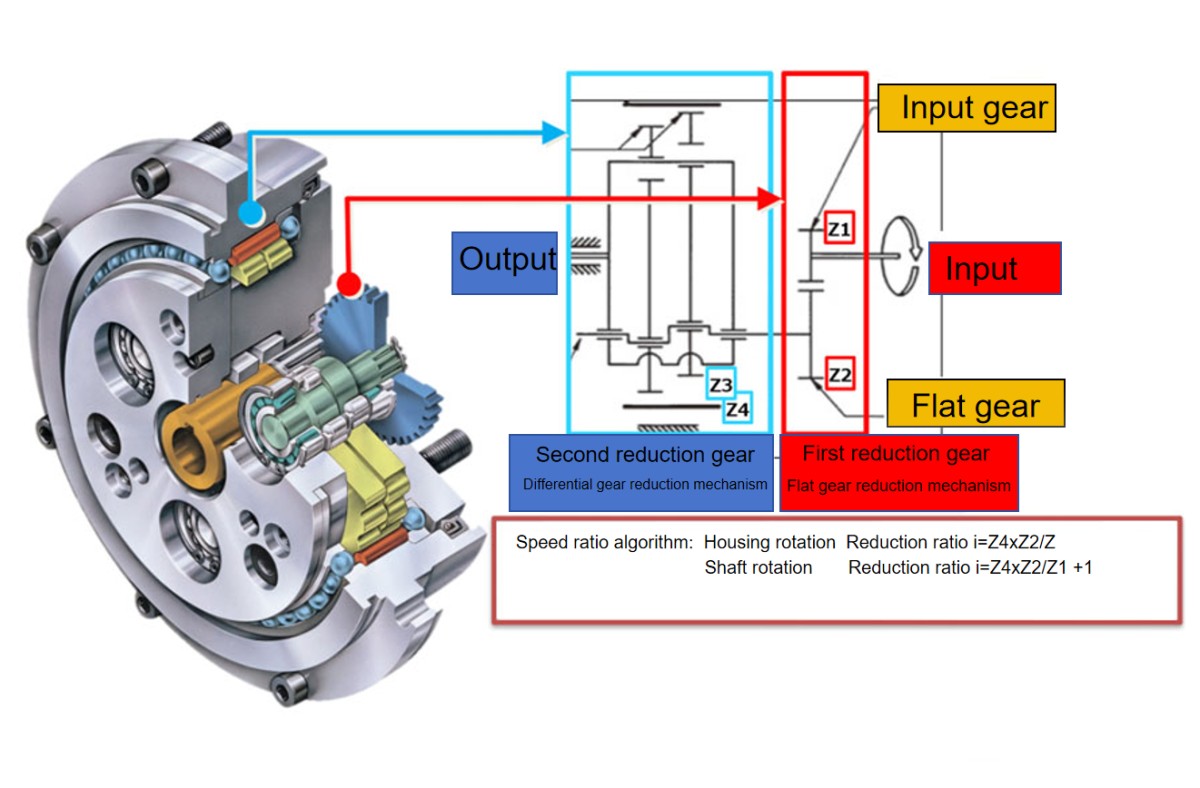

The backlash (gear clearance) is reduced to the limit through the pinwheel mechanism. Even under heavy load conditions, it can still maintain smooth rotation and stable torque output, achieving seamless collaboration with industrial robots. For example, when working with multiple welding points on an automotive line, it can reduce the impact of thermal deformation on the welding gun’s path and adapt to high-speed start-stops and frequent direction changes in welding tasks.

Improved durability and maintainability

The cycloidal pinwheel contact mechanism is used to achieve a low-wear, long-life design. The HONPINE RV reducer effectively reduces operating and maintenance costs by reducing maintenance frequency.

Wide range of speed ratios

With a wide range of speed ratios, the optimal speed and torque combination can be provided for different working conditions and loads. This not only improves welding and processing efficiency but also achieves compatibility across multiple scenarios.

Why choose HONPINE RV reducer

HONPINE RV reducer can be seamlessly connected with mainstream servo motors, shortening the integration time. We can provide technical support and recommend or customize the optimal reduction ratio according to customer needs.

Stable weld bead formation is not only related to "appearance quality" but also directly affects the improvement of "structural strength and durability", making it an important quality indicator in modern welding workshops. These characteristics of HONPINE RV reducers can effectively suppress variations in weld bead width and penetration depth, reduce porosity and crack formation, and comprehensively improve welding quality.