● Introduction

Features

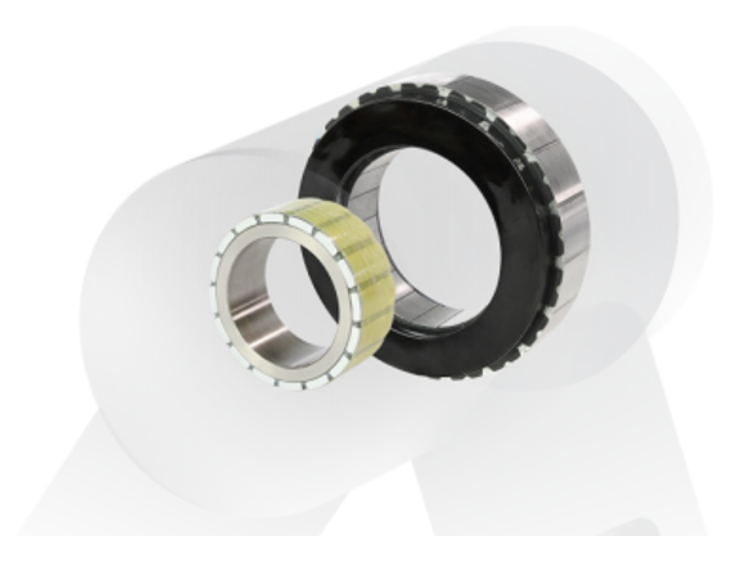

Removes traditional housings and frames, reducing volume by approximately 30%-50% and significantly lowering weight. Ideal for space-constrained, integrated systems.

● High Power Density and Torque Output

Utilizes multi-pole and multi-slot designs with optimized permanent magnet arrangements, enhancing torque density by 20%-40% to deliver greater torque per unit volume.

Reduces iron and copper losses, improving efficiency by 10%-15% compared to conventional motors.

● Efficient Heat Dissipation and Low Thermal Loss

Employs vacuum potting technology combined with high thermal conductivity materials, boosting heat dissipation efficiency. Temperature rise is reduced by 15%-25%, extending operational lifespan.

● High Dynamic Response and Precision

Directly drives loads, eliminating backlash from gears/belts. Response speed increases by over 30%, achieving micrometer-level positioning accuracy.

● Quiet Operation and Low Maintenance

Eliminates mechanical transmission noise, operating at sound pressure levels below 50dB. Simplified structure reduces wear-prone components, lowering maintenance frequency by 60%-80%.

● Customizable Integration Flexibility

Supports parameter customization (rotor/stator dimensions, magnetic waveforms) for seamless integration into robotic joints, medical devices, or other systems, adapting to diverse design requirements.

Specification

Sheet 1

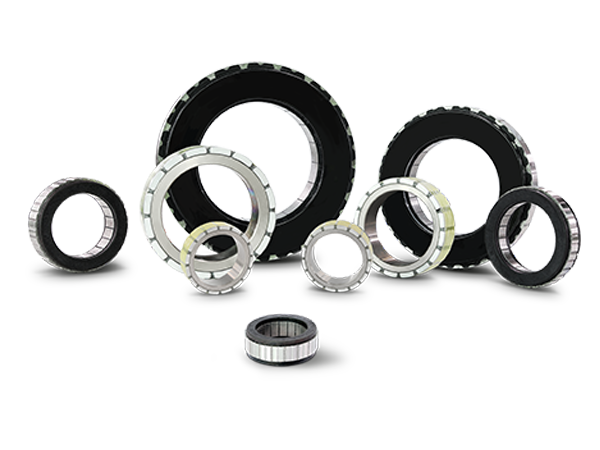

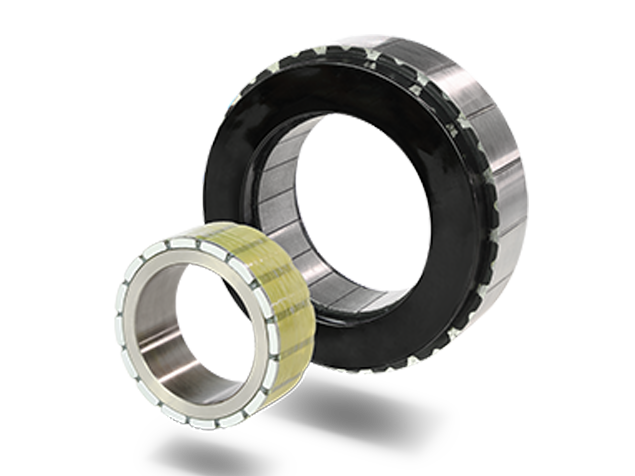

- frameless torque motor

- frameless direct drive motor

- frameless drive

- frameless torque drive

- robotic frameless torque motor

- Frameless Rotary Motors

- frameless servo motors

- Brushless Torque Motor

- brushless direct drive torque motors

- high torque brushless

- high torque brushless servo

- motor brushless torque