● Introduction

Features

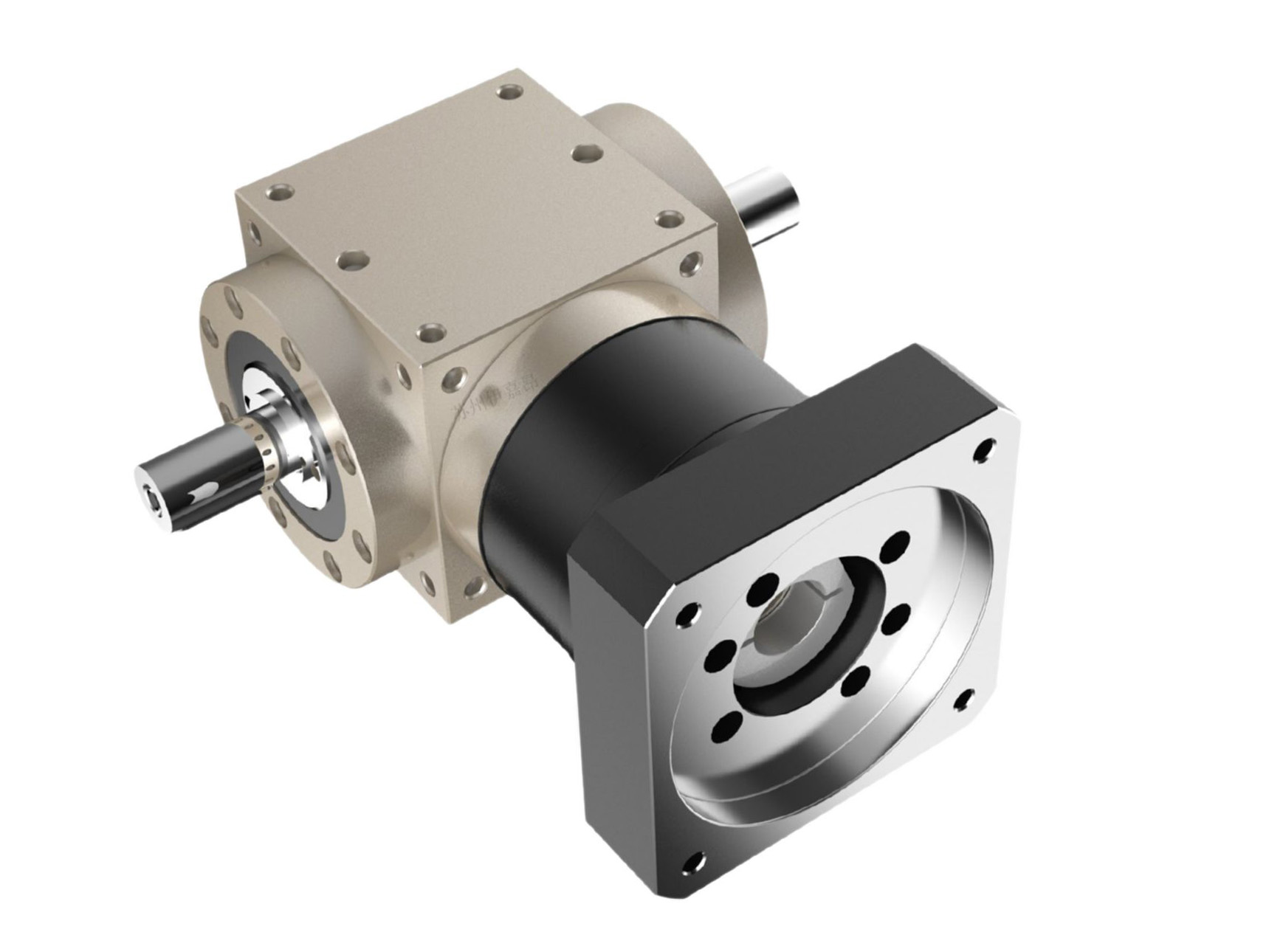

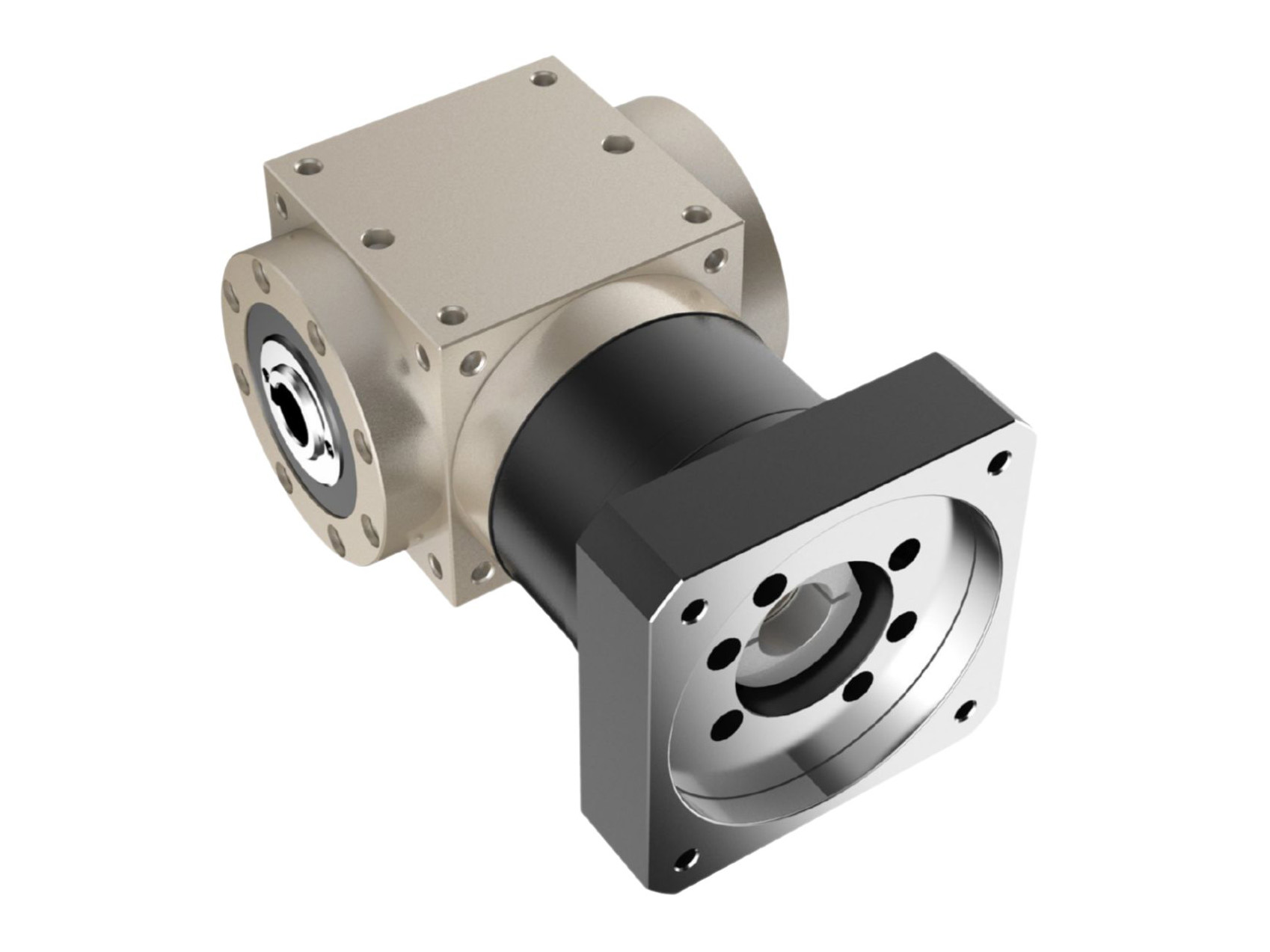

● User-Friendly Design

Features a shaft bore input and a connecting flange for direct motor connection, ensuring ease of use.

● The internal bevel gear structure and perpendicular input/output shaft arrangement minimize equipment footprint, making it particularly suitable for confined installation spaces.

● High Transmission Efficiency and Low Energy Consumption

Employs precision gear meshing and an optimized lubrication system, achieving a transmission efficiency of over 95% while reducing energy loss.

● High Precision and Low Noise

The combination of helical or bevel gears with precision machining results in minimal backlash, accurate positioning, smooth operation, and low noise levels.

● High Load Capacity and Durability

High-strength materials (such as premium forged steel) and heat treatment processes enhance load-bearing capacity, supporting significant radial and axial loads and extending service life.

● Diverse Output Configurations

Available in various output configurations: hollow input with shaft output, hollow input with hollow output, shaft input with shaft output, and shaft input with hollow output.

● Suitable Applications

Ideal for lifting platforms and single-motor driven multi-module systems.