Development of HONPINE mini harmonic drive

Standard harmonic reducers have been widely used in the fields of missiles, satellites, drones and other steering gears. The wall thickness of the standard harmonic reducer flexwheel is σ=(0.01~0.0145)d, where d is the flexwheel pitch circle diameter, and the meshing tooth height is h= (1.4~1.6)m, where m is the gear module;

HONPINE adds correction coefficients to the standard harmonic reducer and optimizes the design and adjustment of key parameters to obtain a small harmonic reducer with high structural strength, long life, and can be processed and manufactured. By correcting the flexwheel wall thickness and the flexwheel displacement coefficient, the meshing gear depth is adjusted to improve the gear load-bearing capacity without affecting other motion characteristic indicators (transmission accuracy, starting torque, etc.). By limiting the range, the design and manufacturing cycle of small servos is reduced, saving R&D costs; then the values within the range are iterated into the standard harmonic reducer design calculation method for design verification, and the optimal target parameters are screened out, and then the optimized design indicators are obtained to complete the processing and manufacturing of the small harmonic reducer; it ensures the mechanical and motion characteristics of the small harmonic reducer, and without changing the design principle of the harmonic reducer, the application scope of the harmonic reducer is expanded to small harmonic reducers, meeting the requirements of small mass, small volume and high performance reducers, and expanding the application field of harmonic reducers to small UAVs, robots and other fields.

Advantages of Mini harmonic drive

HONPINE has achieved the goal of reducing the size of harmonics while greatly improving installation accuracy and reducing production and installation costs through the application of various advanced technologies such as flexible wheel shape optimization and special materials. Compared with traditional harmonic reducers, the axial length is reduced by more than 30%, and the weight of the whole machine is reduced by 40%. It has a major breakthrough and can achieve lightweight while ensuring the accuracy of the whole machine.

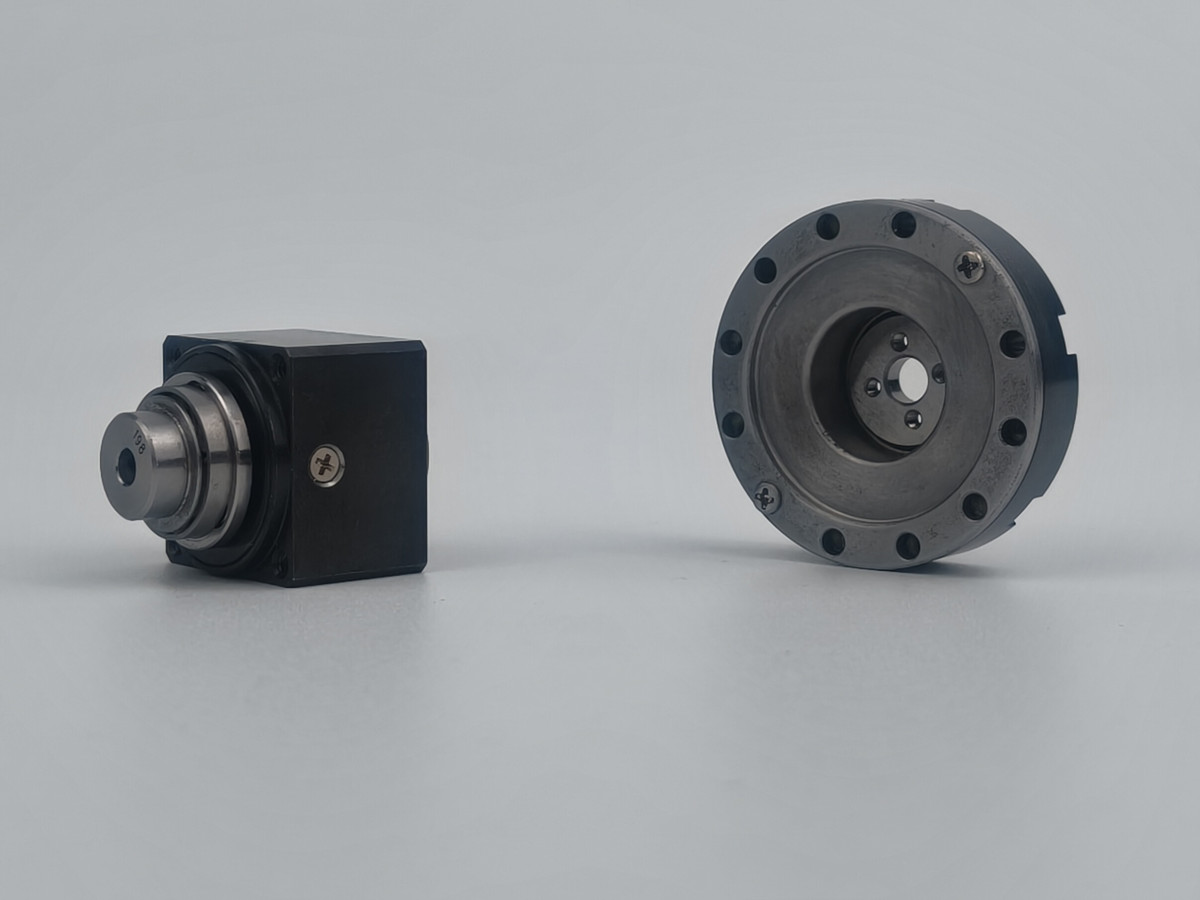

HONPINE mini harmonic drive classification

HONPINE mini harmonic drive currently has two series, SHD series and CSF series, of which CSF-mini series provides a variety of different input and output forms. For example, shaft input and hole input, shaft output and flange output, etc. Contact us for more product information.

Why choose HONPINE

As a supplier of harmonic reducers, HONPINE has strong technical strength and its own R&D center. HONPINE harmonic reducers have the characteristics of high reliability, high precision, high torque, long life, large speed ratio, small size, high cost performance, etc. They are widely used in robots, aerospace equipment, CNC machine tools, semiconductor manufacturing equipment, precision machinery drive control and other fields. Especially in the industrial robot industry, the characteristics of high precision, high torque, large speed ratio can be brought into full play.