The latest advances in humanoid robotics are not the result of a single technological leap, but rather the fusion of more affordable and advanced hardware and software. The development of AI systems, motion control systems, and robot bodies all play vital roles in the overall progress of humanoid robots. Major players are investing heavily, with countries and industries providing varying degrees of support to promote large-scale deployment. Robot components such as harmonic drive reducers are also constantly evolving and achieving technological breakthroughs.

Market Trends of Humanoid Robots

According to Bank of America Global Research (B of A Global Research), humanoid robot shipments will see strong growth over the next decade. This growth will be driven by rising end-demand due to an aging population and labor shortages, improvements in technology (especially AI and motion control) and product design, lower Bill of Materials (BOM) costs, and the expansion of end applications. BofA Global Research is optimistic about long-term demand for humanoid robots as they begin to be used on a large scale in homes and service industries.

B of A Global Research projects that global humanoid robot shipments will reach 18,000 units by 2025. By 2030-35, they expect annual shipments to reach 1 million units (representing an increase of 400,000 units over 2025 levels, and cumulative global sales reaching 10 million units). This equates to a Compound Annual Growth Rate (CAGR) of 88% from 2025 to 2035E.

The Difference Between Humanoid Robots and Industrial Robots

Industrial robots typically execute pre-programmed processes and tasks based on modular algorithms, pursuing static accuracy in specific, standardized scenarios. Humanoid robots, conversely, must adapt to highly uncertain and open-ended environments, integrating multimodal information from auditory and visual sensors to autonomously plan and execute actions. This represents a combination of manufacturing and AI technology.

The Basic Structure of a Humanoid Robot

The typical humanoid robot structure can be divided into three layers: the AI System, the Motion Control System, and the Robot Body:

Artificial Intelligence (AI) System: The "brain" of the humanoid robot, primarily composed of AI chips and algorithms. Responsible for high-level information processing and decision-making (task decomposition, environmental understanding, model reasoning, etc.) and human interaction.

Motion Control System: The "cerebellum" of the humanoid robot, consisting mainly of controllers and motion control agorithms. Primarily responsible for motion coordination, body balance, and path navigation.

Robot Body: Contains the core hardware for environmental data collection and motion execution, including the vision system, sensory system, actuators, dexterous hands, energy system, and structural materials.

Control System

The control system of a humanoid robot has two layers:

The Artificial Intelligence System handles high-level control (information processing, decision-making), supported by AI chips and algorithms.

The Motion Control System handles low-level control (motion coordination, body balance), supported by controllers and motion control algorithms.

Chip: Chips used in humanoid robots mainly include processor chips, control chips, and bus management chips. Processor chips form the core of the robot's "brain," primarily used for model inference and computation. The dominant technology currently is a CPU (Central Processing Unit) plus GPU (Graphics Processing Unit) architecture, which is also the most mature.

Control Algorithm and Embodied AI: The control algorithm is the core of the humanoid robot control system, enabling the robot to perceive its environment, process vast amounts of sensory data, make real-time decisions, and execute actions. Traditional control algorithms use a hierarchical design between the AI system ("brain") and the motion control system ("cerebellum").

Conversely, some leading humanoid robot companies are adopting end-to-end models. These models can generate action commands directly from input sensory data (vision, language, force, etc.), bypassing complex intermediate processing steps, and are executed by a single neural network. Compared to hierarchical methods, end-to-end models offer stronger generalization capabilities, higher efficiency, and lower requirements for feature engineering. However, they typically require large amounts of training data, which can be a short-term bottleneck.

Robot Actuator Module

The drive system is the core of humanoid robot motion control. It includes electric, electro-hydraulic, and pneumatic actuators, which drive or control system components by converting energy into physical motion. While electro-hydraulic actuators offer the highest output torque, they are more expensive and carry the risk of oil leaks. Pneumatic actuators are cheaper but have lower precision and output force. Due to their high precision, fast response, and reasonable cost, electric actuators have become the mainstream choice for humanoid robots.

Electric actuators comprise

Servo Drive

Servo Motor: Typically a frameless torque motor for outputting torque.

Transmission System: Harmonic/planetary reducers (for rotary actuators) convert torque; planetary roller screws (for linear actuators) convert rotary motion to linear motion.

Sensing System: Encoders and torque/force sensors for collecting system data.

Based on function, electric actuators are categorized as rotary actuators (for rotational joints like neck, shoulder, wrist, elbow) or linear actuators (for joints requiring linear motion like arms, ankles, knees).

Dexterous Hands

Dexterous hands are key end effectors for humanoid robots to perform complex and delicate tasks, such as picking up small objects and handling fragile items. Current designs from different manufacturers range from 6 to 42 Degrees of Freedom (DoF), compared to the 27 DoF of a human hand. Generally, a 6-DoF dexterous hand design can achieve 60-70% of human hand functionality.

Reducer

A reducer is a mechanical device used in humanoid robots, industrial robots, and machine tools to reduce motor/engine speed and increase output torque. The three main types are: planetary reducers, harmonic drive reducers, and RV (Rotary Vector) reducers. Currently, in mainstream humanoid robot designs, harmonic drive reducers or planetary reducers are commonly used for rotary actuators.

Planetary Roller Screws

Planetary roller screws are high-performance mechanical components used in linear actuators to convert the rotary torque output of a servo motor into linear motion. Compared to ball screws, they offer advantages like longer lifespan, higher load capacity, higher transmission efficiency, and better rigidity. Therefore, they are widely used in industries such as humanoid robotics, aerospace, and heavy machine tools.

Frameless Torque Motor

The frameless torque motor is a type of permanent magnet motor. Unlike traditional motors, it consists only of a rotor and a stator, without a housing, shaft, bearings, or feedback system. This eliminates the need for mechanical transmission parts like gears or shafts, driving the load directly via magnetic force. This design achieves high torque density and performance in a compact structure and is commonly used in applications requiring high torque and low-speed performance, such as robotic joints, medical equipment, and aerospace systems.

Sensory System

The sensory system of a humanoid robot collects environmental data, sent to the motion control module to adjust the robot's movements. It includes cameras, LiDAR (Light Detection and Ranging), and various sensor types. The number of sensors can range from 30 to over 200, depending on the robot's functions.

Vision System

A complex, intelligent system using multiple camera types (stereo cameras, Time-of-Flight (ToF) cameras, structured light cameras) and LiDAR to capture visual information about the surroundings, enhancing the robot's perception, navigation, and motion control capabilities.

Force and Torque Sensors

Force sensors measure applied force or pressure (mainly for linear actuators), converting it into an electrical signal for measurement, control, and monitoring. Torque sensors measure applied torque or rotational force.

Inertial Measurement Unit (IMU)

Measures the robot's acceleration, angular velocity, and other motion parameters, helping the robot sense its own posture, motion state, and maintain balance. Also used in consumer electronics, automotive, and aerospace.

Tactile Sensors

Commonly used in the dexterous hands of humanoid robots (typically 10 sensors per robot, one per finger) to measure force and pressure between the sensor and an object. They mimic the receptors in human fingers, a crucial part of human skin.

The Harmonic Drive Reducer Plays a Key Role Here

Amidst the explosive demand for humanoid robots, harmonic drive reducers dominate due to their advantages of lightweight design and high torque density, while planetary reducers complement in heavy-duty scenarios. Currently, two major technical paths – flexible wheel fine-blanking processes and rigid wheel material substitution – are driving iterative upgrades in reducer material technology. Long-term mass production of 10 million humanoid robots is estimated to drive a ¥19.15 billion market for harmonic drive reducer steel, with a potential ¥3.83 billion market for fine-blanking steel/ductile iron technology substitution. Precision reducers are the core components of robots.

Harmonic drive reducers offer significant advantages: small size, light weight, large reduction ratio, and high torque density, enabling efficient operation in confined spaces. They also maintain good performance under specific conditions like confined spaces and medium-radiation environments. These characteristics have led to their widespread use in mobile robotics. In contrast, precision planetary reducers are primarily used in components with lower precision requirements, offering higher rigidity, longer lifespan, and relatively lower cost. Therefore, in humanoid robots, the combination of harmonic drive reducers and precision planetary reducers effectively meets the power transmission needs of different joints.

The Future of Humanoid Robots

Increased Demand for Customization

As application fields expand, new requirements emerge across different sectors. Customization demands are rising. Industrial logistics robots, service robots, medical rehabilitation robots, educational/research robots, entertainment IP robots, and special-purpose robots all have distinct design requirements. For example, special-purpose robots need to operate in harsh environments, educational robots demand high cost-effectiveness, service robots focus on upgrading interaction capabilities, and logistics robots require high action flexibility. HONPINE is committed to providing solutions for diverse robot manufacturers and developers.

Stricter Cost Control

Humanoid robot development is fundamentally a contest of capital, which ultimately seeks returns on heavy investments. Automakers, mobile device companies, software firms, and others have joined the industry. Competition among humanoid robot suppliers will become the norm.

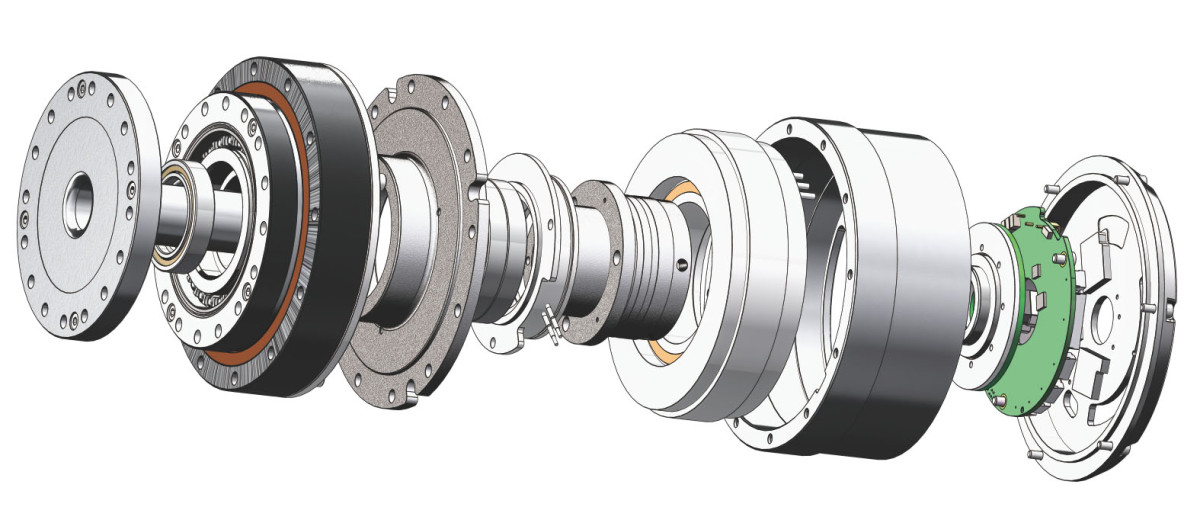

Modularization and Fast Installation

As robot functions continuously upgrade, the ability to assemble robots quickly to bring new features to market rapidly is a key competitive factor. Many customers directly purchase pre-integrated robot joint modules. A typical joint module consists of a reducer (usually a precision harmonic drive reducer), a drive, an absolute encoder, a brake, a frameless torque motor, an incremental encoder, and the integrated joint assembly. Purchasing modules instead of sourcing individual parts reduces procurement costs, shortens installation time, and accelerates R&D.

How to Choose a Robot Parts Supplier

Choosing a supplier with strong R&D capabilities is crucial for effective one-to-one technical collaboration. HONPINE assigns dedicated technical support to each customer, providing one-to-one service from model selection and post-sales installation guidance down to details like harmonic drive reducer grease sealing guidance. Many customers say HONPINE is like their reliable partner. Throughout humanoid robot development, whenever challenges arise related to precision transmission, we are always ready to help solve them. This plays a key role in accelerating development timelines and reducing R&D costs.

HONPINE specializes in precision transmission equipment including harmonic drive reducers, planetary reducers, robot joint modules, robot rotary actuators, and RV reducers. As an integrated company handling sales, production, and R&D, we have provided precision transmission solutions to over 200,000 companies since 2018. We offer one-to-one guidance and establish dedicated technical communication groups for each project. Efficient service and cost-effective products are the reasons many customers choose us and maintain long-term partnerships.